I will be using a Pro Scientific Homogeniser with a 20mm X 200mm saw-tooth generator probe

@woftam

I know but that was the model he mentioned and so I would presume those persons starting out would search for that model. No harm done just thought the wording was weird.

No harm done just pointed out their are cheaper options to do it like he does.

Me just started this past year. But I did search web locked for different articles. Actually didn’t realize elr had a forum

Found everyone referred to steeping juice when mixing or after mixing

But never how they step

So I called my local vape shop who told me when they make juice the put it in hot water until the water cools to help steep the juice. Then mix it again.

So

Mix,

Heat a little to thin the juice( hot water from k-cup)

Mix

Then let set or vape depending on what it is.

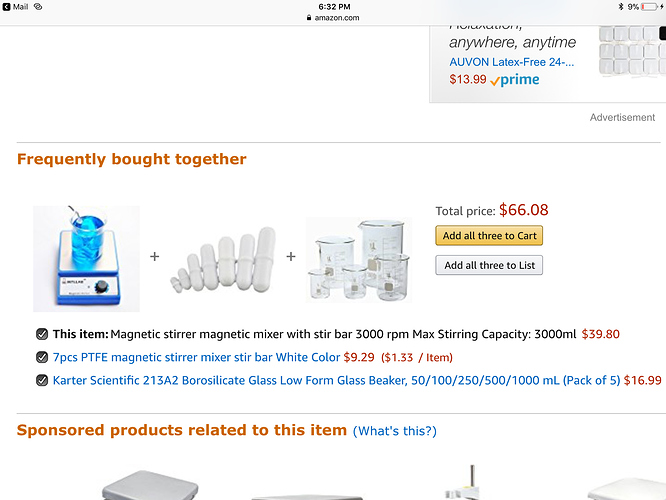

Looking into gettting a 4 space hot plate mag stirrer. Usually mix several large batches at one time.

Should run me around $300

Doing a search here on ELR for “homogenizer” will bring up several results. I have referenced them several times and in fact have been going down this branch of the rabbit hole for many months. I don’t own one. It is the science behind their mostly commercial use that Interests me.

However there are other juice sites where owners/ users provide some very good info. Search reddit and look for posts by abdada. To quote him:

“The reason a quality lab homogenizer works is because it shears the molecules together versus mix/blend them. That’s a big difference.” And again:

“Steeping involves a few different processing, including homogenizing and letting off harsher top note volatiles (basically evaporation).”

“A homogenizer is NOT a mixer. It actually takes the liquid into the probe and slams the molecules together without introducing air. Then it shoots them out at a ridiculously high speed to smash into the container walls.”

“One thing to also note is that homogenization doesn’t actually remove the steep process entirely, because in most e-liquid blends there are some lighter volatiles you’re praying will air-off eventually because they taste foul or hide some of the other notes. So just shearing the shit out of a mix isn’t enough, it does still need some steep time.”

Just thought you all might find this interesting.

That’s an ok mixer definitely lacks power

I would look for the SH rating on the mixer and i would suggest not buying anything under SH-3 for juice

My understanding is that for our use we would want a standard probe not a saw toothed probe, as the saw toothed probe is for macerating tissue samples, since we are just mixing liquid a standard probe would actually do a better job. I actually started looking into this a few weeks ago so I may be way off base but that’s the information that I have garnered from my reading.

That is my understanding too. But, that unit he ordered is a very good one and I think the same as abdada owns. Clearly it is the probes that cost more than the motor. If he bought it new he can probably exchange it. If used I dunno. If used I hope he got a certificate of decontamination. They use these for some real nasty stuff-bones-cancer cells etc.etc.

That’s what I’m saying, probe is the priciest part and I don’t think I would feel comfortable buying a used one, I also have been trying to figure out how easy they are to clean, you know the whole cross contamination thing, when I mix I will make 10-20 different recipes at a time. But stir bars are cheap.

Yeah man I don’t know whether I could use a used one or not. Just imagining what it may have been used for would probably get to me. They are easy to clean. But as you know from my prior posts, I stir. I have time to wait for things to steep. But my method of stirring is different than any other I have seen here. And that method comes from studying the commercial usages of equipment in the flavoring business. In fact, I heat PG /VG to 60 C and stir it by itself. Then cool and add flavoring at different temps according to what I am using. Then I add nic.

See I toss everything in the beaker, then put it on my mag stirer, then it stays there for as long as it takes to get a good mix, depending on how much I’m mixing it may be 10 min to an hour or more.

That’s is definitely different than I have ever seen anyone else mix, what in your opinion are the benefits?

smoothness…better wicking… better flavor. I started exactly how you do it. But when I got to the bottom of a gallon of VG I noticed that it was considerably thicker. I use heat, but there aren’t many flavorings that I would heat to 140 (60C) but there are some. In your reading I’m sure you’ve seen several places that state that VG will not homogenize at lower than 60C. While I am not homogenizing per se, I am setting the process in motion. That is why I have the overhead stirrer. Its for large quantities of VG mostly.

Edit: I will not stir in any open container. Everything else was the same as you when I started.

Maybe I should clarify a little more. When I discovered that my Vg was thicker and heavier at the bottom of the gallon container, I realized that mixing by weight was inaccurate. It was obvious. So I make my PG/VG solution by volume and them weigh it. Then mix by weight. So it began as a way to be more consistent. But by stirring the shit out of it at +60 C I noticed better flow and wicking along with the other things mentioned and _maybe_a little shorter steep time. But definitely a better steep.

@mrpipes @Cutlass92 good morning I have been reading your posts and its great to read so many positive things. I would like to put your minds at ease thought, all my equipment that I will be using will be brand new, I would never use a secondhand probe for the same reason’s you stated too lol. as for cleaning them, the probe is easy to disassemble and put back together again.

According to wikipedia homogenization is the same thing as an emulsion. A culinary emulsion is made with a blender. I have a blender that i use only for vanilla creams and custards and i get very good results. In case your wondering it appears as little to no air is being drawn into the juice. Then 4 hours @ 130 - 140 and 3 days later its pretty close to a 6 week steep. Maybe a cheaper alternative ? I am very interested in homigenizers and wiil follow this thread, i want one but not sure if its worth it.

In my opinion, it would be worth it as you wouldn’t need to rely on heat Or anything like that, The cost is a lot but if your making for a lot of people the time saved would pay in the end. and your end Product would be a lot better. At least this is what I’m hoping, I have spent a lot of time researching this

and everything I have found so far leads me to believe that this is a more productive way of making a high-quality liquid.

I have read things from other people about using blenders. The claim is that it is the next best thing. The downsides claimed are aerating the mix and loss of top notes when the container is opened. But I’ve never tried it. When using a stirrer I always use a sealed container. Stirring will inject some air but it is trapped in the stirring container. Little to no air is injected by the Homogenizer.

I’d like to have one of these too but I can’t justify spending that kind of money when I just mix for my wife and self. But I have a pretty nice metal lathe and a vertical mill. If I could lay hands on one for an hour to measure and check certain things, I’d sure make one LOL. A variable speed router would be fully capable of powering it and easily adapted. (Wheels turning in head)

The definition is correct but there are special emulsion attachments (Screens) with these things. Terminology is I think every mixers enemy. But after all “steeping” IS homogenization. I have come to despise the term “steeping” but it isn’t about to go away.