If you send them an email be sure to include a link to this very public discussion of their products. This is the best place to broadcast a positive Customer Support resolution … money well spent on advertising

I was just gonna make a post about this. What did you end up doing with it?

I hope not…

Sh!t, that sucks.

Ya, I noticed that too.

EXACTLY!!!

Pet Peeve of mine too and I’m not even a repair tech.

Me Too! ![]()

Yep, me too! LOL I hate when people say " there should be no reason for you to over torque your rdtsubohmatomizer etc." but there are a few reasons why and how it can and will happen. Although, apparently not for some individuals. ![]()

I’ll say. He fixed a mod of mine that I thought for sure would be trash.

wouldn’t that be wonderful. I have yet to find the “right” one. How about you, cuz I would love to have it? ![]()

@Sprkslfly for me the ohms are jumping. I thought maybe a short. I haven’t opened it up yet, I wanted to check the forum first. Is it a major issue, I was hoping I wouldn’t have to open her up? I know I’m grasping in the dark hear, I was hoping you might have an answer.

Thanks Y’all

Start simple.

Check your grub screws (for the coil). Are they tight?

Remove the atty and make sure the 510 is clean of debris/etc, and also that it’s dry.

If the above checks out, do a full field strip on the atomizer.

Pull the coil(s).

Pull the glass.

Pull the screw(s) out of the base of the 510, so you can remove the peek insulator.

Sometimes (on rare occasions) I’ve seen eliquid getting down through the center channel of the posts, and saturating the peek insulator.

Ordinarily, I would maintain that (I can’t think of a reason why) eliquid shouldn’t be conductive. But the reality is it most assuredly can be (and to varying degrees).

In short though, simply doing a full disassembly, and cleaning the peek insulator (as well as the inner channel of the positive segment) has resolved impedance stability issues on several occasions for me.

Bear in mind, I don’t use cartridges anymore though.

I have seen bad cartridges cause intermittent readings (years ago when I was still using the nautilus mini bvc’s, and the original clieto). So for those who still use cartridges, always check a different cartridge before you go too deep.

Quality control on most cartridges was shit back then. I’d be surprised if it’s improved much.

After you’ve checked the atty points above, the only thing left is the mod (unless I’m forgetting something).

The 510 is always the first thing to check there.

Make sure you’ve got good continuity through the center positive pin, all the way through the wire to where it connects to the pcb.

Same check for the ground.

Not much else the average user can do beyond that.

I’ve got more tools on the way for working on SMD boards (thanks to the stimulus). So I’ll be able to dig even further into things than before, thanks to having additional proper tools for the job.

If all else fails, and you want me to have a look, you know how to find me! ![]() lol

lol

Banged the 510 part back in with a hammer (gently of course) and still use it. Occasionally still has problems but a tap or two on the top seems to fix it. Still using the Brunhilde MTL on it, but take it off to do anything at all now rather than doing it on the mod.

I took mine apart and it looks like the positive wire is broke at the solder. It must have happened when I opened it. Anyway, I soldered it back on and put it back together and it still jumping ohms but I am pretty sure it will be ok ( i hope)

WIN_20210113_09_13_51_Pro|690x388

I’m just biased against press-fit.

They make it borderline impossible to service, which automatically says to me that they had zero intent from the initial design of supporting it.

I totally read this in a heavy Canadian accent ![]()

![]() #AvE

#AvE

“release the schmoo!” -Uncle Bumblef**k

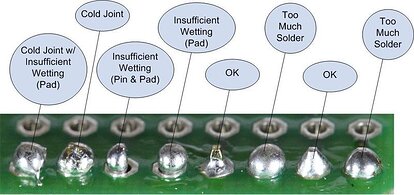

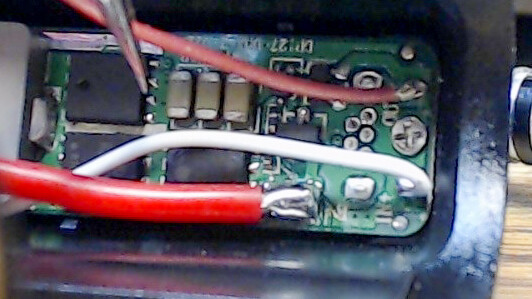

There might be a poor solder joint somewhere else that changes resistance as it expands and contracts during hot/cold cycles while in use. Whatever part of a circuit a weak solder joint is in can result in downstream or side affects, possibly causing fluctuations in resistance reading as you are seeing. I would hit those solder joints and any others that look dull/rough, have visible micro cracks, or just don’t have enough solder to fill the hole.

The one on the lower left in the bottom highlighted circle may not be bad, it’s hard for me to tell from the photos

I’m really just trying to convey the message that a high percentage of electronics product failures are due to  “shitty Chinese soldering”

“shitty Chinese soldering”

https://learn.adafruit.com/adafruit-guide-excellent-soldering/common-problems

I often add things to my initial post. See

a high percentage of electronics product failures are due to

“shitty Chinese soldering”

Personally, a large percentage is due to the BS change in legal standards of solder…

Ever since the mandate of ROHS (lead-free), there’s been issues with soldering and joints in general.

In the past, even a poor joint would operate within effective enough parameters (though not ideal) to maintain the intended integrity of the circuit.

It’s a different world now though.

Funny how things change.

In my younger days, recycling meant you paid to have something repaired, and continued to use it for another 10-20 years.

Nowadays, recycling means you “put it in the right bin” (because the piece of shit you bought was so cheap that it’s not worth paying someone a living wage to have it fixed properly). ![]()

![]()

@JiM210 there’s only one joint in that pic that’s ok. That’s the second from the right.

(The fact that someone thought the other one was ‘ok’ is also part of the problem.)

~I wrote this earlier today and forgot to hit the send button~

me the ohms are jumping. I thought maybe a short.

@Dan_the_Man I have a mod with the 510 receiver pin that is recessed a bit too deep. I discovered this when I paired it with an Atomizer that has a 510 pin that’s a tad short. The two would just barely meet and it was vaping fine at first. After awhile I started noticing fluctuations in the resistance reading that were outside of the normal and eventually resulted in a “dry atomizer” display message and the mod refused to fire. I eventually realized I can tighten the tank just a little and it would hit again and/or the resistance would return to within normal range. After awhile the problem returned and I was able to repeat the exercise, validating the problem. I then shimmed the Atomizer non-adjustable 510 pin with a cardboard washer I fashioned from scrap. That fixed it. I later found ya tiny O-ring to replace the cardboard washer.

See, spoke too soon. Using the 120w it is again showing “load fail short” regardless of which atty I put on it. Fast becoming a candidate for the bin. My other Coldsteel 120w works fine and never had a problem. Surprisingly, the one that doesn’t work came from a newer batch going by the serial number…

So you never contacted the manufacturer? I get not wanting to bother but just saying, I’ve had 2 mods replaced and one refund.

It has been out of warranty for ages @muth, but I did send them an email just after my original post here. Never received a reply from them.

I had no idea that I could use to much solder. Ok, maybe I should say, that the photo shows “too much solder” looks like one of mine that I considered a “good” solder.

I think I should practice but I don’t even know how to do that…

Occasionally still has problems but a tap or two on the top seems to fix it.

A friend of mine suggested J-B Weld. Idk if you’re still using it, just thought I’d pop in to offer that suggestion. I thought of you today because my Cold Steel took a fall with a tank on it and the tank hit the carpet in such a way that it dislodged the 510 (just a wee bit). It still works but I tapped it back in with a rubber mallet.