After a successful rebuild of a Triforce stock coil, I gave the Crown coil a shot. Here’s how I did it…

Disassemble your stock coil retaining the coil head, the metal contact pin and the rubber insulator. Remove all the cotton except the cotton covering the juice flow holes.

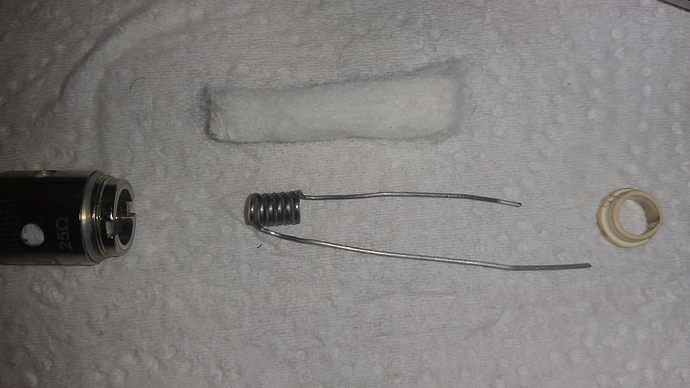

Make a 6-8 wrap 4-5mm ID spaced coil with long legs. A small ID will have a more restricted air low.

Cut 1/4 to 1/3 inch wide by 2 1/2 inch long strip of cotton. Try not to fluff it.

Insert your wrapping tool and carefully bend the legs in the same direction on opposite sides of the coil. I make sure the outer wire is a bit longer than the inner wire. This will be important later

Pin your cotton under outer leg and reinsert your wrapping tool. Make two complete tight wraps of cotton around the coil. Try not to have too much excess cotton above and below the coil. It will block your air flow.

TIP @quitter1 says if you wet your cotton with eliquid it will be easier to form and wrap.

Sounds good to me… I’m adapting his method on my next rebuild. Thanks for the tip @quitter1!

Make sure the outer leg doesn’t make contact with your coil. Not only is the cotton your wick… it’s also your coil insulator.

Your coil should look similar to the photo below. Now insert your new coil into the coil head. It may be a bit snug going in so twist it in a direction that you wrapped your cotton, so your cotton doesn’t unravel.

Once it’s in, apply a little extra pressure in order to pack the cotton a little.

If you can’t get your coil to go in, unravel one wrap of cotton and try again.

At this point I used a small screwdriver to pack and tidy up the cotton and the coil. You can also reinsert the wrapping to keep the airway open.

Pull out your wrapping tool and put your rubber insulator back in with the shorter wire inside insulator and the longer wire outside of the insulator. These are your positive negative legs.

Excuse me for not having a clean insulator. I forgot to take these photos on my first rebuild, so I ripped apart another coil to complete this tutorial

Now reinsert your metal contact pin and trim the excess wire as flush as possible. I wiggle my excess wire back and forth until it breaks flush.

Check your resistance… if it check out ok then you’re set. Remember to saturate your coil before you fire it. You can also reinsert the wrapping tool to make sure the airway open. You should be gtg (good to go).

Don’t expect perfection on your first try. Just as with anything… it will take a little practice and your own modifications to consistently get it right… Good luck!

Please comment if you know of a way to make this easier.