The TCR setting for ss316L should be around the .00090 - .00100 depending on your preference I use .00095 (but I also dont use TC much anymore)

Well, the TCR for SS316L is 0.00092. Make sure you have the correct wire called out for the TC mode.

*Edit, Wolfman got in first…

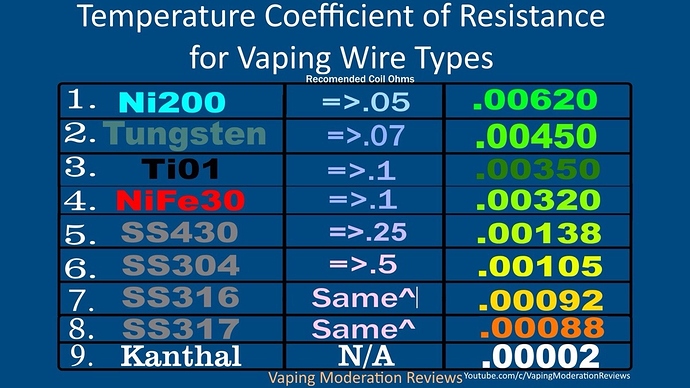

TCR is definitely more “interactive” than power mode. When right, it’s a great vape that will help you keep dry hits at bay. But there’s a lot of settings you need to manipulate. The TCR value is a big one… Sounds like (and Woffle’s chart concurs) you are in Ti01 mode. TCR is the rate of a particular metal’s resistance change over the heat range, and the mod needs to be using the right wire numbers in order to fire correctly. And when you get your base reading make sure the coil is at ambient room temp first. Without authoring a book here, that should get you to a better starting point. Other TCR Masters can also chip in here.

When you have a temperature limiting (TC) mod, it usually has settings for Ti (titanium), Ni (nickle 200), and SS (usually SS316). Those are just fixed (or named) TCR settings for the most commonly used vaping metals.

Some mods allow for other custom TCR settings, e.g. if you want to vape on SS304 or NiFe30. If you use SS304 on the regular SS TC setting, it will kind of work but not great, simply because there is a difference in TCR between SS316 and SS304 but it’s not a huge difference.

The higher your TCR value is, the more accurate you vape experience will be. The lower your TCR value is (e.g. SS), the more accurate and expensive your mod needs to be to give a relatively good vape experience.

This is why some brands, like Evolv DNA or YiHi are often praised for their TC performance. They work with good and accurate hardware (and software) and they’re more expensive because of it.

Most mods can easily handle Ni and Ti in TC but when it comes to SS, you’ll find that a lot of mods struggle.

When your wire heats up, the resistance will rise according to your TCR. The lower your TCR value, the lower the percentage of rise in resistance is. In other words, if you have a high resistance for your coil, a low % can still mean a detectable increase in resistance. If you have a very low resistance for your coil, the low % could be too small to properly detect any changes and your temp control functionality will fail.

That is why Woftam’s graph shows the recommended minimum coil resistance for each metal. Of course, that is no hard rule. If you have proper hardware in your mod, you could go lower and have a proper TC experience. If your hardware sucks, it may even struggle at those values.

SS is a very popular metal because it’s cheap, it’s easy to work with, it’s relatively safe to vape on and it works both in power and TC modes. However, the extremely low TCR value of the metal doesn’t make it a good candidate for good temp control. If you like vaping on this wire, it would be good to invest in a mod that has excellent SS TC performance and if you don’t want to invest big, talk to some people that mostly vape TC and ask for some cheaper recommendations that still do well.

@anon28032772 I think that’s a more detailed explanation of TCR settings low vs. high than I’ve ever read anywhere. Thanks for posting that

I PM’d him that and told him he should copy/paste it to look good.

Kidding… the man knows his TCR for sure.

I know jack shit about TCR  I just use the standard SS settings on my mods and never play with TCR mainly because I vape only on SS316. I just read stuff and put it in my own words here.

I just use the standard SS settings on my mods and never play with TCR mainly because I vape only on SS316. I just read stuff and put it in my own words here.

I mainly use DNA devices that perform well enough for me in standard settings (i.e. no scorched cotton and still the power that I need) and other devices that don’t work well in standard settings will be collecting dust, go to friends or serve as a backup if I ever have a mod that wants to give up and die.

Well maybe you shouldn’t post up a well worded, and correct narrative, only to follow up with a statement like that!! ![]()

just kidding about the jack shit… I do understand the principle but I’m sure there are others that delve deeper into the subject for who I’m just another noob.

Same here. But I’ve been doing the same builds over and over that I now just use the mod to confirm the 0.21 or 0.07 builds that I typically do. Works out.

Same. I found the thicker gauge wires tend to come out more beautifully. But they also tend to have larger spaces if pulled too far apart. This is a simple thing to learn across different wire gauges and metals. It was @Pro_Vapes who taught me this method with Titanium, and man does it ever look and work tremendously.

So on the shikra that I have been using since Xmas it has TCR TFR TI01 SS 304, 316, 317 as well as NI200. It room temp my coils read .33 ohm in power mode when heated they jump to .4 or .41.

Now in ss mode at 415f and set to as 316 the shikra does nothing. But the coil is also reading at .14 till I got the fire button and then it jumps to between .38 and .41.

Same settings in sombra it has a nice flavorful warm pull to it. Reads .33 at room temperature and goes to .4 when fired.

I have never seen any coil jump so much from the normal sub ohm tanks to the RTA and rdas

I set TCR to .93 and at 415f I feel like I’m getting burnt hits. However if I lower it to 385f it hits for about 1.5 seconds then stops.

I don’t know those mods, so can only speculate. The mod chipset may be removing those extra zeroes (aesthetically I mean) but the SS316L TCR should be 0.00092, definitely not 0.93. That’s magnitudes of difference and will produce undesired results

So did you remove the atty and put it back on before you switched settings? Some mods remember the last coil Ohm numbers an use that without asking if the coil is different. Just a thought.

Ok so both sombra and shikra read in TCR at 0.0000.

However I set it back to SS 316;@ 385f and pressed the button to read the resistance which then changed the reading to. 34 and now I can use it in ss mode instead of just using tcr. So I’m glad it wasn’t my coil build that was the problem.

Oh no one said anything about the coils i built I would love some feed back on how to improve them.

The pic with the ‘resistance lock’ may have been the issue. And you’re preheating for a full second which may be getting them warmer faster than you like, but dunno.

Well, my Daddy used to say “If you don’t have something nice to say…” Just kidding. Yeah they’re a little out of uniform and that can have an affect on the heating and hot spots. The more you practice the better it will get, would be my advice. Try pulling the wraps all as eveny as possible before you squoosh them back together. And in my experience, if I go over 7-8 wraps it isn’t as pleasant. Ramp up and cool down is affected and wicking can be an issue getting juice quickly to the center of the coil. But others probably have different experience.

I suspect that is exactly what is happening. I do 28ga stainless fused Clapton’s at 3.5 mm. When wicking I make sure cotton is tight but loose enough to be pulled back and forth before I make my cuts. Feather out my ends so they aren’t smooched in the wells. Haven’t had a dry hit since.

I also do that, the "burnt’ hits stopped once I was able to get the setting correct.

I will keep practicing the pulling them apart more.

To be honest I am quite shocked that I was able to even make the coils in the first place. Having low vision limits me on doing certain things and I didn’t think I could even make them in the first place.

Another trick to make nicely spaced coils:

This isn’t hard although it sounds like it is.

-

□ Use two pieces of wire cut to length. Insert one end of two separate pieces of wire into the handle of your "coil master clone" coil wrapping tool, trapping the loose ends on the handle with your thumb.

□ On the twisty part of the tool there should be a screw you can unscrew just enough to twist both pieces of wire at the same time. If the screw is not out enough the wires will cross and end up on top of each other when you twist the wraps

□ To manually start the first part of the first twist pull both wires about half way around the steel post part of the tool making sure that both wires are side by side without crossing each other.

□ Slide the twisty part over the steel post and line up so the bolt on the twisty part catches the two wires.

□ As long as you don’t push too hard when you twist you should be able to wrap your coil the number of desired turns. Make sure the two wires remain side by side during the twisting.

□ Unscrew the handle part to release the steel pin so you can slide it out from the wrapped coil, using caution to prevent distorting the end of your wire.

□ Remove the captive end of the wire from the handle(the wire ends that were held by you thumb on the handle at the beginning).

□ With the coil out put steel pin back into handle, reassemble the handle.

□ Slide your coil back onto steel pin.

□ Bend the loose ends gently so they extend straight from the first and last wraps.

□ Now grab one end of one wire with needlenose pliers and gently pull the one wire away while you hold the handle firm. Just make sure your two wires don’t cross in the process of pulling and keep your fingers out of the way.

You should be left with one nicely spaced coil.

Another simple trick, which I can’t find the thread, read here at ELR, is to use a screw as a base to wind the wire …

Isn’t that the way coils was made before coil master? I tried that way years ago and failed so bad I didn’t try making coils again till noe.

It’s an old trick indeed but it never appealed to me. If I wouldn’t have my coil jig, I’d just use a regular 3mm screwdriver. It works for regular micro coils and the pull apart and push back together technique is so easy for spaced coils no matter which type of wire you use. It’s actually very difficult to screw up.