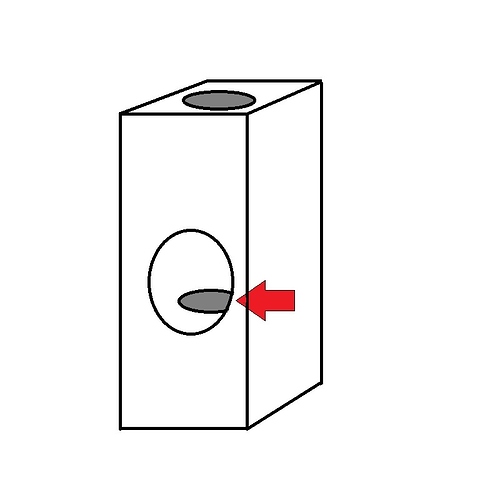

The problem I’m having with the Advken Ohmega (and many other RBA’s as well) is they cut coil legs. Some of it may be due to the screw used, but I know with the Ohmega it’s a problem with the machining of the posts. Rather than drill the coil leg hole and then tap it till it just goes through that hole, the screw hole is obviously drilled through the leg hole and beyond, creating a little crater in the bottom of the leg hole so that when the screw is tightened it acts as a scissor. Now I ain’t no graphics dude so the drawing below is just my best attempt. But the question is what can be done if anything to fill that hole?

I wonder if perhaps you could put a dab of epoxy to cover the opening.I have used devocon products with great success.I have also used a product called pig putty as well as the old standby JB weld.I would check the label of whatever you wish to use but I am sure they have some that would not leech into your e-juice.

I know devocon offers it with bits of metal to increase strength , I have milled and threaded it without problems.I would check into the high temp rated products just to be safe.

On several of my atomizers I have removed the screws and filed the screws flat to keep from cutting the wire.However on this situation I would think that the flat bottom would only help to slice the wire by pushing it into the hole.I would think that a small bevel on the screw may help tremendously

http://www.all-spec.com/products/Devcon/Tapes_and_Adhesives|Adhesives|ADH-00/.

If you could get the hole clean , you think you may be able to fill with solder?

Rookies

Drill the hole deeper with the correct tap drill for that thread. I will take mine out and see what it might be. Tap the hole deep enough to sink another set screw in just far enough to keep it in there. Re-drill the cross hole to remove the extra set-screw sticking up into the thru hole.

And by the time you buy the drills, taps and extra set screws you should just buy the aromamizer for 19.99 and spend the extra you have left over on flavorings.

I have all the tools needed in my vape room. You don’t?

Having a small metric tap set handy with all the tanks and such most people have - to me that just makes sense. But if you don’t, there are always friends here willing to mail a tap to get the job done  No sense throwing away a tank that he likes.

No sense throwing away a tank that he likes.

I would assume the lower portion of the hole was drilled past the lead holes so they could use a plug tap instead of a bottoming tap (which sucks ass in stainless). It probably already has a few threads in it anyway.

Thread size is an M2 x .4. I am willing to bet in one of those old tanks your don’t use you will have some set screws of the same size. See if you can get one to thread down past the lead hole and into the lower portion of the hole.

Mix up some JB weld and put it in the bottom hole let harden and you’ll be ready to go.

I do have most of the tools including a series 2 Bridgeport and a Clausing 10x36 lathe at my house.I do not know if SthrnMixer does or not so I was offering an easy tool free alternative that one can pick up at any napa or ace hardware.However after being called a rookie I will quit offering advice and leave it with you my dear Mr.Expert, Have a great day.

Hey now. I was just teasin’ - notice the “;)” Pay attention to the smileys. That is what they are there for!

Don’t take it the wrong way. I would have said the same thing to my 7’ tall 450lb co-worker in jest and he would have just jabbed me back with a smartass comment as well. We are all friends here. I am sure some good aircraft epoxy would work just fine. But, (now here is another jab) the title of the thread is “Hey you machinists”. Not “Hey you guys with bottles of glue”

I was just offering up a solution based on what I think I know about @SthrnMixer and what I figured he was capable of handling. Even if it required some help by me sending him a tap and drill bit to get the job done. I was following the thread when he bought the tank in question. I have one myself. And I know how much he likes it. So please don’t be offended by me just giving you guys some shit

[quote=“BoyHowdy, post:8, topic:44034, full:true”] after being called a rookie I will quit offering advice and leave it with you my dear Mr.Expert, Have a great day.

[/quote]

Hell I thought he was talking to me. I wasn’t at all offended because I’m no rookie. You have to know something to be a rookie and I don’t know squat  [quote=“LordVapor, post:9, topic:44034”]

[quote=“LordVapor, post:9, topic:44034”]

I was just offering up a solution based on what I think I know about @SthrnMixer and what I figured he was capable of handling. Even if it required some help by me sending him a tap and drill bit to get the job done. I

[/quote]

Maybe 30 years ago when I had good eyes and steady hands I might take something like that on. Besides I got a feeling when those damn Griffins finally get here this thing will be sitting anyway.

Well I am the electrician next to you machinists just enjoying the conversation. Lol

I had cataract surgery on both eyes at the age of 41. A year later I had laser surgery to remove the cataract forming on the membrane behind my now silicone lenses. And ever since they cut on me I have no depth perception, I can’t see shit unless it is between 12"-14" from my eyes. One set of glasses to drive, one set to read, one set to work at the PC, and I just throw the damn things on the table when I am running the machines.

What if you were to use a guitar string, like a D or wound G, and run it through the wire hole back and forth to debur the wire holes on each post?

Only thing is it’s not a burr problem. Even if it were I doubt the bronze windings would hold up to stainless. Good thing too because I use Elixir strings and they cost more than $20 a set.

Unrelated, but you can buy 3 packs of good sounding strings for the same price as elixirs…and nothing sounds better than new strings, so change them more often and still break even.

Big fan of John Pearce strings, acoustic and electric. If not you, somebody will thank me

PS, don’t use the whole string…just the part you cut and discard, or even an old one after a change.

And it doesn’t hafta hold up, just k nock down the sharpness.

They all seem to have a lil bit of a well down there.

Yes, all the cheap stuff from China sure does seem to have that. I’s a flaw in my book. A manufacturer’s defect But hey, I’m the one who has bought the cheap stuff so why should I expect anything less? ![]()

True dat, but I have oily skin and that’s hell on wound stings. So when I first got Elixers and found that my wound strings would last 5 times as long I was sold. But if I played more often I would probably pick up just whatever - Dean Markley or D’ Addario whatever. I’ll grab some Pearce strings next time and check em out.

I fill all of my Clone RDA’s that have this issue with a little piece of copper tape (I’m an Electrician for BUD have access) wadded up and stuffed in the hole then tighten the lug down all the way to compact it. Its a non issue afterwards. If you don’t have it the next best thing it to take some 14g or 12g wire and snip a little piece and drop it in from the top. Problem solved easy.

I have wondered if some aluminum foil might also serve the same purpose. Thanks for the tip!!

I was thinking that maybe dropping some solder (silver solder) into that divot might do the trick…Silver solder is fairly hard, so I don’t think it would wear out too rapidly…not sure if you have the room to work with the actual solder gun head, but maybee heating around the post and putting the solder wire into the hole while heating the post area…but then again, I am not sure if there are hidden solder connections within the system which could be heated and compromised…also was thinking that maybe a Crossman BB with a flat surface filed into it …Crossman BBs are copper…Daisy BBs are brass I believe, so maybe either one?..