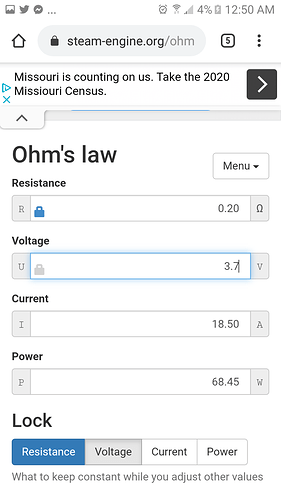

From what I understand if the amperage in the ohms calculator is higher than the battery’ s amperage then it goes into a danger zone.

The power supply batteries will be connected in series, increasing total battery voltage possible (otherwise, they would “battle” each other, and consume unwanted currents between themselves).

If two coils are series-connected, then a doubling of the (output drive, average) Voltage is called for. That is (probably, don’t know) how things go - because the Current value flowing through the coils will be identical (Kirchhoff’s Law).

If the coils are parallel-connected, an increase of the (output drive, average) Current is called for. However, the individual coil Currents will vary if the coil Resistances differ (and they will, somewhat).

Your Mod displays Voltage, Current, Power (Watts) measured across/through the (composite) Coil(s) Load. Those measurements are what you need to rely upon. Know your (composite, that is - as series or parallel combined in operation) Coil(s) Load Resistance Value, and work from that with displayed Voltage or Current (or just Wattage, as that equates to some maximum and average Temp values).

I have never wound coils with #22 Gauge wire (only #26 and #28). Sounds like a “rigorous” task ?

As I described above, in the age of solid-state, voltage-multiplying, high-frequency switching-supply Mods, any such (simplistic, single battery hard-wired to load Resistance) viewpoints may fall short. Best to keep (continous) battery Current load to something as low as 1/5 of the Max continuous discharge Current (under some internal battery-cell Temperature maximum value). I recently purchased some 10 Amp (rated continuous discharge) batteries (LG MJ1s) that appear very likely to be (voltage) “drooping” under only a 2.5 Ampere (total composite, referenced to the battery Current draw) load. Margin is good !

The reason I threw 22 gauge on there was just for example and I had seen someone do the same build on YouTube so it was fresh in my mind. When I had 26 on there for some reason I was getting less than one wrap. Sounds like I have a lot more research to do. So far it’s been pretty overwhelming especially with most of the terminology in your replies being completely unfamiliar to me. I guess I just need to find an example build that would be viable and proven safe for my setup and try to understand that specifically then move on to my own tweaking of numbers to continue to better understand the limitations and stay in a safe, consistent zone. Right now on a pre made super mesh coil at .17 ohms with two 18650 15 amp batteries at 67 watts, it’s showing that I’m pulling 3.36 volts and 19.8 amps during a draw.

My favorite setup is a dual fused clapton in SS316L. They’re 3mm ID, 7 wraps with a dual 26g core and I use 40g wire to clapton it. They ohm out at 0.15ohm. If you’d do the same with kanthal, you’d be closer to the 0.3ohm resistance.

Fused claptons are parallel wires bound together by a wrapping wire. The resistance is mainly achieved by the thicker parallel wires (electricity chooses the path of least resistance) so the thickness of your wrapping wire isn’t going to influence the final result very much.

The thicker the wrapping wire is, the easier it is to make but the heavier the coil, the longer it’ll take to cool down after a puff. SS already cools down relatively slow, Kanthal is much better BUT, once you’re used to vaping on SS, it’s hard to go back to Ka because of taste. SS also does both power and temperature control (if you have a decent mod that can handle the lower resistances in TC).

Fused claptons are very popular because they’re very easy to make and they’re little flavor bombs. All you need is a drill, 2 spools of wire (core & wrap), a beadalon spool tamer, a vise and some swivels. The wire will wrap itself for you!

Have a look at the coil building show offs thread, there are some great examples and techniques for coil building.

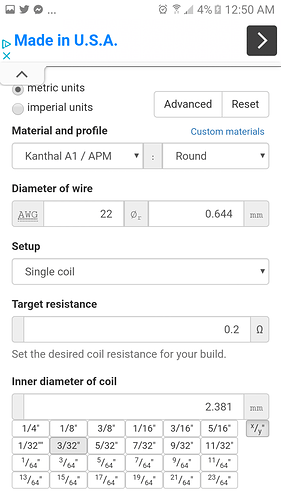

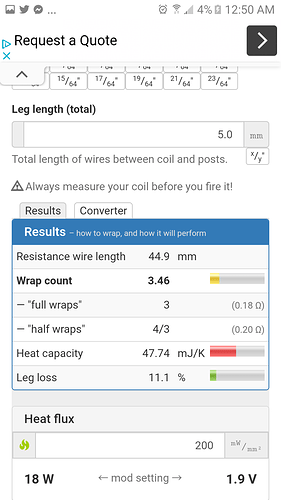

(Single Coil):

For #22, 3mm inner diameter, ~10mm lead-length, in order to achieve 0.17 Ohm with Kanthal A1/APM:

With SS 316L:

So I guess heres another question… is the reason why it’s safe for it to go to 20 amps on my vape because it has two 15 amp batteries and not just one? On one 15 amp battery 20 amps wouldn’t be a good idea? Also, the coil build you showed for the kanthal says 15 watts. Is that the recommended wattage? The recommended wattage on this super mesh coil is 60-80. Would making my own coil out of kanthal then allow me to vape at a lower wattage because of the material and size of the material compared to the thin mesh they use in the coil I’m currently using? That’s another confusing part to me. Why the difference between the two wattages. Maybe this is obvious and I just need to sleep on it. It is awful late at the moment. Lol I appreciate all the help so far.

Batteries are almost surely series-connected, thus share a single common (similarly limited) Current (continuous discharge maximum).

That “15 W” displayed is just an (arbitrary) number (generated from the calculated Heat Flux).

Here is your above-described coil (in the “Advanced” mode):

If your batteries are in series, you can add the max voltage of each battery (amperage will remain the same). If they’re in parallel, amperage will be added but voltage remains the same as a single battery. It’s always good to know these things before purchasing a mod, batteries etc. If you don’t know much about electricity, go for multi battery mods and purchase only batteries like Sony VTC 5a or Molicel P26a (for 18650 batteries) that are high amp batteries. And ask questions like you do here

Usually, the lower your resistance is, the higher the wattage needs to be to heat up your coil to produce enough vapor. MTL coils are usually high resistance wires. They use small, fine wires for those coils and don’t need a lot of power to heat up.

DL wires (or mesh) has a lot of metal (lower resistance) and needs much more power to heat up.

-updated after a kind correction from @Raven-Knightly-

I think that (as perhaps you intended to state above ?) this reflects the situation (of series-parallel):

If your batteries are in series, you can add the [voltages] of each battery ([current] will remain the same). If they’re in parallel, [current] will be added but [voltage, only if exactly matched in value] remains the same as a single battery.

If (paralleled) batteries differ in any amount in voltage, the higher voltage battery will dominate (as well as source a lost discharge current flow through the lower voltage battery).

To keep things simple, the amount of metal in your coil defines how much power (P=V * I or Power = Voltage x Amperage) you need.

Different metals have different internal resistance, which is one parameter you can use to control your final resistance. The thickness of wire is another parameter.

The thicker your wire is, the less resistance you will have.

Think of a water hose. A very fine hose won’t let a lot of water through, it has high resistance. A big hose will have much less resistance and let a lot more water through. It’s similar with wires and electricity.

To heat up a wire, it’s like building up pressure in that water hose. You won’t need a big pump to put pressure on that fine hose but if you opt for a big hose, you’ll need a much more powerful pump.

Low resistance wire, whether it’s mesh or a round-wire coil, means you have a lot of metal to heat up and that’ll ask a lot from your batteries.

Yes, but since he is already confused, I didn’t want to introduce more words that are only going to confuse him even more

I propose “flipping” current and voltage in your statement (with my stated provisos) to reflect reality.

Oh man … you’re absolutely right.

I’ll be back in a while after I’ve had a couple cups of coffee

@Bigsmoke188 Listen to raven

Just looked and the aegis legend connects it’s batteries in series. I can’t figure out why I’m running into such a road block with aspects of this. It’s like understanding it isn’t enough , I also have to meet it’s mother if that makes any sense lmao. If 2 coils are the same resistance, .17 for example, and both are made out of kanthal is there a reason why steam engine is recommending 15 watts for a basic single coil and the one I have now is rated for 60-80 watts through the manufacturer? Is it the difference in wire style? That the basic wire coil is an actual wire as opposed to thin kanthal mesh? I guess I assumed when I made my own coil if it was .2 ohm I’d go by the wattage I used for the pre made coils I normally buy. But the wattage displayed on steam engine makes me think my assumption was incorrect because it’s such a massive difference.

Right. The batteries are series connected (doubling the maximum available battery Voltage potential). Those batteries (should, advisably) have the same maximum continuous discharge Current ratings (same make/model batteries).

(For a given physical coil-wicking setup built on the same deck), your best “gauge” looking back in time to previous practices is the Power in Watts (reflecting peak/average Temperatures previously preferred).

Working Backwards from “Load” to “Battery”:

Knowing the (Load) Watts, add a fraction of that amount ( < 1/20 ?) for Mod Power consumption, and from that sum of Powers (Load + Mod), calculate the common (maximum average) continuous total discharge Current flowing through the battery cell(s) at a fully-charged Voltage (4.2 Volts per cell, or any particular somewhat lower voltage perhaps more representative). The maximum continuous discharge Current rating of the batteries utilized should be at least 4 times (better yet, ~5 times) the multiple of the calculated Current (process described directly above), for best performance (minimizing “drooping”).

As long as the Mod in question (at the output-drive point) can generate sufficient Voltage corresponding to some (composite, net load) Current to dissipate N-Watts of Power in some (composite, net) Coil(s) Resistance, the Mod should be able to do it. The specified range of possible load Resistances reflects the electrical limits of the device.

Again, the “15 W” displayed is just an (arbitrary) number (generated from calculated Heat Flux) ! ![]()

Stainless Steel is lower Resistance than Kanthal A1/APM - which enables one to construct (feasible, in this case, single) coils [such as using ~5 turns (SS), as compared to using ~2 turns (KT), respectively).

.

For some semi-energetic “heavy-duty prior Nerditude”, some important “factors” are discussed here:

Summary:

The use of thicker wire gauges in order to achieve a lower total Coil(s) Resistance requires more Coil Power (Watts) in order to achieve the same 10%-90% Temperature Rise Time (of increases in the Temperature of the Coil/Wick Interface). As a result, the particular coil wire gauge that is used in creating a coil(s) determines a specific range of Coil Power (Watts) within which an “acceptably fast” 10%-90% Rise Time can be realized - with the required amount of Power (Watts) increasing with wire thickness. Maximizing (inner) Coil Surface Area while minimizing Coil Mass minimizes 10%-90% RT.

The amount of power has a lot to do with the amount of cooling your coil gets, as well as with the resistance, how well your wick performs and how you suck on your mod. Also coil material and type of coil play a role…

So for every new coil you use, you should start very low and build up to where you feel good about it.

Some metals heat up and cool down very fast. Some wire types, same thing. Very thin wires heat up fast and thick bulky wires/coils will need more power to heat up and more time to cool down.

Coils are cooled by both liquid and airflow so the harder you suck and the better your wick works, the more power your coil can handle.

I’ve learned not to trust the recommended wattages on commercial coils because I’ve ruined plenty. It’s also one of the reasons why I love TC (temp protection) so much because if you choose a wattage that’s too high or your wick can’t keep up, you mod will shut off (or regulate) power so you don’t burn your cotton, ruin the coil and give you an unforgettable experience.

15W for a .17ohm coil is really low. I’d start around 40W and build up from there. If you have a .3ohm coil, start from around 30W and build up. Once you’re building coils and testing different options, you’ll get a feel for what is acceptable and what not. After a while, most people find their preference and stick with that and then there’s no more (or a lot less) experimenting.

Were those failures loss of plating (and corrosion interfering with heat-transfer), or actual breakage ?

Some are good but a lot were over-estimates, especially on the higher wattage range. In the beginning I needed a good throat hit and I guess I pushed the coils too much at the higher recommendation, burnt cotton.

I quickly switched to DIY coils. At least you can make what you want that way and use whatever metal you prefer. Both kanthal and nichrome taste like metal to me and ruins the taste of a juice and neither can be used for TC to prevent scorched wicks.