Uhhh… I doubt that, there must be “another factor” . there are no known endothermic reactions using PG. So most likely you have one of the following issues:

- measurement error.

- failure in the engineering or function of your “stable” heating method.

- some unseen “sinking” of the energy in the system. Near an air conditioner duct?

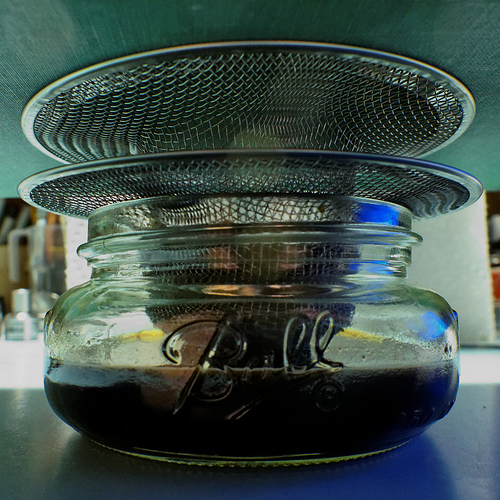

If you have a iPhone or can otherwise snap a quick picture of your set up and post it here that would be most helpful.

Also you could perform a simple experiment using water in place of the tobacco/PG mix and then using the same equipment track the temp curve again and see what you get.

I will say (not to toss in un-necessary scare verbiage) … BUT, if what you had there was in fact the result of a chemical endothermic reaction then you MUST toss the mixture in the garbage and NEVER attempt to vape it ! Chemistry that is powerful enough to sink heat from a electrical line power source of more than a few watts will be toxic to ingest. Usually oxidizers like Potassium Nitrate are used commercially for emergency “cold packs” of the power necessary for the temp drop you describe. Although KN03 is not a poison, the reaction by products will be unknown, and you should not be so bold as to experiment with ingesting them.

Let us see a picture of your set up and also please list the exact brand and details of the tobacco sample you used, and the source and label description of the PG sample you used.

-![]()

EDIT: I now re-read your post and see that you are suggesting the reverse explanation of what I noted above. I was supposing that you had described an endothermic reaction, but i see that what you suggest is that the there might have been an initial oxidation reduction reaction that produced heat in the initial stages of the maceration. My response to that is what I posed above in reverse, if you will pardon that stretch. So again, there is no known self initiating re-dox reactions with PG and tobacco that would produce sufficient heat to get the result you describe, and again, if such chemistry was present, you should toss the product. Again, re-run the whole thing with plain water and see what you get. And let’s have the details on the ingredients you used and a picture of the set up. Thanks