Good luck on that !!! ROTFL -![]()

![]()

![]()

So true. I’m a big fan of the dark fired Kentucky, as well as stoved or pressed tobaccos. The word rustic, comes to mind. That wood smoke flavor is what keeps me coming back to blends such as this. ![]() Glad you had success!

Glad you had success!

I got my C&D Dark Fired Kentucky in yesterday and the tin note is fantastic. Just threw it in the crock pot. Got some high hopes for it. I need to get me one of those rice cookers you use.

(also: I my C&D Dark Fired Kentucky in yesterday and the tin note is fantastic. Just threw it in the crock pot. Got some high hopes for it. I need to get me one of those rice cookers you use.)

What caught my eye here is the Cold PG 1.2 year extraction. As you know @Kinnikinnick was the inventor of a very clever way to shorted these times to typically 6 months or less. Suggest you try the Kinnnikinnick Hot Bump Start" I took it one step further and used an Utra-Sonic cycle for 30 mins/ON 30 mins/OFF for 12 hours. and get very good results shorting up total extract times to 6 months. There also is a well know industrial technique to do this with commercial homogenizers but the equipment costs are very high, well beyond home DIY.

Here is a rambling discussuion from a private PM about tobacco cell wall disruption ideas:

( Please forgive the fact that this had to be cut from a private PM, but for a while all tobacco related discussion, and really any technical discussions, on this forum had to be taken to PM as the Forum went through a growing stage when every post to such a subject met with a barrage of GIFs of old Monty Python, or vulgar off topic, vicious intentional and destructive derailment)

There are two major groups of substances involved with our kitchen chemistry, one is flavonoids, the other is alkaloids (dVaps nicotine and WTAs Haha…)… i am not going to get within a hundred miles of the alkaloids for reasons previously noted many times, but a mechanical approach to speed up flavonoid extractions seems like a reasonable and worthwhile and food-safe goal for the NETS fanatics.

I thought about taking a chemistry approach (to speeding up our flavor extractions / steeping) and using cellulose digestion to release / destroy the cellulose walls greatly enhance carrier liquid contact with the flavonoids. That is the reason, I think, that there is all this extended multi- month steep time. Cellulose is the enemy. It makes sense, that the reason the 6 hr hot steep hit at the beginning of a PG cycle cuts the steep time from 6 months to one month, is that the structure is deteriorated by the heat. Also possible to use chemical digestion of the cell walls, big side benefit there is we can prevent fermentation into glucose. But I want to take the track of the high shear method and mechanically just rip the cellulose wall apart. I want to stay away from a chemical approach, for all the reasons I have ranted about in many of my previous posts. FYI chemical cellulose digestion is a very advanced technology right now, it was heavily funded by waste water treatment,… But also was looked at extensively by the Wine Industry, as they are dealing with EXACTLY the same problem when making wine as we are here with the tobacco flavonoid extractions. I think if I look around in the right places, this whole technology is already available to us as almost ‘turn-key’. I need to talk to the people at Gallo Winery, the are just down the street from me in Clovis /Fresno, and they know this stuff backwards and forward.

my growing list of ‘to-do’ things to try with NETs. To a hammer everything looks like a nail. I have a background in industrial chemistry so everything in this subject looks like a piece of process machinery waiting for a proof of concept.

My list so far:

centrifuge filtering

ultrasonic maceration

homogenizer cell wall disruption:

Only bad news is that I think I will hit the brick wall on the home brew high shear mixer. It does not look like I can fudge that here in the kitchen. I am going to see if I can call in a favor with someone that works in a medical lab and run a couple of tests over there. I am also going to drop an email to the pro over at silverson, and get a product application engineer to tell me what I need to do the job.4 .enzymatic cell wall treatment

I have gotten thu #1 and written up some of the results, posted on another forum.

Here is a good one at a very reasonable price:

iSonic P4810+BHK01A Commercial Ultrasonic Cleaner w/ Beaker Holder Set for DIY Liposomal Vitamin C

by iSonic

Link: http://a.co/d/0XwskBM

I was actually just reading a thread on here the other day where you were talking about breaking the cell wall to aid in the extraction. The very first NET I made about 3.5 years ago I believe I did a heat/cool/heat/cool method. It probably worked out great, but there were many other issues with that one that made it unenjoyable (choice of tobacco, VG extraction, and poor filtering.) I decided to dive head first in to the sea of synthetics, and didn’t revisit NETs again until about 2 years ago when I got a sample pack from Truebacco. I really liked those, but knew there was no way I was paying those prices for something I could do myself. Second time around with NETs I did a heat assist on some Peter Stokkebye Black Latakia (the goal was to use this as an additive in hybrid recipes.) I’m pretty sure I went a little too hot with the heat assist, and messed up that batch. So I decided I’d just go cold and wait the good wait. I ended up forgetting about 4 or 5 jars I had going, hence the 1.5 years in the jar

The current batch I decided to give it another go with the heated kickstart, but this time pay a bit closer attention to the heat. So far I haven’t seen anything jump over 150*, so I’m thinking I’m good. I did see an interesting thread on reddit the other day where the topic of microwaving juices to aid in faster steep times came up. It got me to thinking about a quick zap at the beginning of an extraction to possibly aid in that cell wall disruption, but I work on the production side of things in a photochemical machining plant… so it’s kind of outside of my area of expertise. Any thoughts on that? Most I could find was on Pipe smoking forums talking about using the microwave to speed dry before smoking.

I would not even try using a microwave, Reason being is that Microwaves cause extreme, very high localized heat zones, / flavonoids are very delicate and heat sensitive molecules, You can destroy their structure with heat. Stay in a uniform bath type heat conduction environment not to exceed 145F and better yet at 125-135.

I have used the catchall term flavonoids’ but these desirable components that we want to extract and carry to our vape juice is broad range of amino acids, polyphenols, aromatic acids, Lignin, and other phenolics. Other delicate items that are now considered to be some of the most important aroma precursors responsible for tobacco flavor are sugar esters, beta-o-glucopyranose (a glucose tetraester) This and the more predominant sucrose tetraester, as well.all these compounds are subject to auto-oxidative reactions, which cause degradation, in response to heat, which is both an accelerant and an initiator in these destructive reactions.

… my 2 cents anyway…

-![]()

Oh, I wouldn’t say I was the “inventor” of that process… I did a great amount of reading and stood on the shoulders of others in the NET world when I was just starting out. For me, the process worked as I hoped and wished. I suggest everyone find their own process… the one which suits them best. ![]()

Thanks for sending me the sample of this extraction. EXCELLENT ! This one is a winner and a keeper for sure.

I don’t know how I missed this one in my NET travels, but I am going to fix that issue immediately and order a tin.

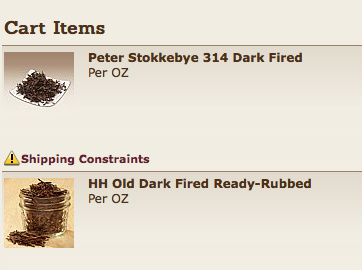

I am on a mission to get some Dark Fired into the jars. @Kinnikinnick had sent me some PS 314 and @ChemicalBurnVictim had send me the HH Old Dark Fired.

I sampled each and they are excellent… Then in a moment of impulse I Hybrid mixed 50/50 of each and wound up with a wonderful ADV. It combines into a robust very smooth, woody, vape with a wonderful ‘tobacco’ room note. Highly recommend NET Heads try this Hybrid mix if you get a chance.

These two are available in bulk here:

I’m pretty sure that Dark Fired is one @Kinnikinnick sent me as well, so I might have to mix a little of this combo up.

Pulled the trigger on my Leaf Only order. Picked up:

Ecuadorian Seco Binder

CT Havana Primed

Brazilian Arapiraca Filler

CT Broadleaf Filler

American Flue Cured Scraps

Izmir Turkish Oriental

Really excited to get these bad boys in some PG.

I found a pot with a Dunhill Robusto cigar maceration that I also forgot about. Made February 2017. I did give it a heat start but I must say it still tastes a lot better with more time. I did draw out a sample before and it wasn’t as good as it is now.

Just going back in this thread I see that was December 2017

Looks good ! I have about 6 jars going right now. It’s the ‘new frontier’ in NET for me. A huge new learning curve, but I think the rewards will be worth it.

-![]()

The time delays in doing pure leaf extractions is one of the issues of working with that type of feedstock.

I already use Ultra-Sonic start cycles with my extractions from Pipe Shop type commercial blends, but am experimenting with extended Ultra Sonic at 1 month intervals over the life of the extraction with single leaf feeds. . Your observation that “but I must say it still tastes a lot better with more time. I did draw out a sample before and it wasn’t as good as it is now.” is an important one. Those of us that are trying to work with single leafs must not underestimate the time frames involved. Anything that can shorten these times should be tried, and either proven to work or discarded as we then make the move to brain storming the next possible best method of approach.

Another issue is that getting to a complete vapable flavor profile will involve ‘blending’ which is a whole art and technique in itself. Also repeatability will be an issue as leaf stocks are highly variable from year to year as the crop and the fermenting from our suppliers change over time. Your Dunhill cigar extraction brought with it the skills of highly skilled professional blenders that rolled the original cigar. If you tried to get that flavor profile by blending individual single leaf extractions from scratch yourself then you are looking at a large mountain to climb. But that’s what makes it a goal worth approaching.

So it seems that it is the NET hobby taken to levels.

I agree with that, especially for people who are just starting the whole NET journey and are impatient to try their concoction, I know I was.

Now it has become less important to me because I have so many NET’s that it would take me years to vape it all so I’m fine with the wait.

I can definitely agree with that. I discovered I like the cigar macerations the best and that they turn out cleaner than pipe is another bonus. I think for now I will just stick to buying a good cigar but you never know what the future will bring.

I’ve been doing quite a lot of things lately that I thought I would never do.

Besides the longer maceration time, is there anything else I should be prepared for? I’m thinking I am going to get a cheap electric coffee/spice grinder to get the tobacco as fine as I can get it before I start the process. Other than that I was kind of planning to go business as usual.

Humm… not sure i would do that. The physics of fluid motion driven by convective heat is really complex stuff, but just my guesstimate of what you would wind up with is a very fine ground solid plug forming on the bottom of the jar and poor transfer efficiency as a result of less fluid flow by the target.

. If you think about it this ‘plug’ will just sit on the bottom with very little fluid flow in or out, of what is effectively a barrier at the surface of the plug. The clear fluid will just sit on top, effective transfer will be, I would guess. very low. Unless, perhaps, you have a method that mechanically re-suspends the fine particles on a frequent basis.

If the tobacco is cut to some imaginary ideal length these pieces would (hopefully) arrange themselves in a ladder like fashion each of which is fully exposed to the fluid, and allow the solvent fluid, driven by convective heating and cooling from the environment to ‘drive’ the fluid around the surface of those particles. I think the ‘trick’ is to find this ‘ideal’ shape and size of the particles.

-But just a guesstimate on my part. Try it and see what results you get.

I was hoping that the density difference between the tobacco “powder” and PG would help keep it in suspension. Though at this point it’ll probably be easier to play around with the idea rather than pen and paper it. Experiments are usually more fun than the book work, and then just winging it along the way until you get something that works. Just to be safe I’ll start with a small bit of some trashier tobacco to test it out. Don’t want to go and ruin my good stuff.

Just sort of planning ahead for a possible fix, and thought about mounting a little motor like this on top of a Ball jar and fixing it up with something to keep it continuously stirring. Now it’s got me kind of wanting to give it a shot even if I don’t get a fine powder like I was wanting. It’s pretty cheap, so I think I’ll pick it up. My wife uses some app to track all of our spending habits. No idea how I haven’t gotten a stern talking to haha.

@ChemicalBurnVictim … I know experimenting can be good for the brain matter, but after vaping your awesome sample of Solani Aged Burley Flake that just cold soaked for 90 days in PG… I don’t see how you could possibly improve on your maceration technique!  But, have fun!

But, have fun!

I ordered and received my Solani ABF (x2 tins) yesterday and already have a jar sealed for a 3 month cool steep.