Oh and welcome

I have no idea what that is, but it’s looks pretty cool

Are you making a flux capacitor?

thank you :))

the video shows the robot at about 30% of its potential top speed.

yes raspberry pi 4B. but the motors are just geared DC motors and not steppers. in fact they have been a bit of a pain and I have considered switching to steppers. but I have made it work with just DC motors. I will upload another video of the final version of how it all works in a couple of days hopefully.

no but if it doesn’t work out, maybe for my next project?

no but if it doesn’t work out, maybe for my next project?

Always worth considering. I love the robot, I expect it can do a fair bit of precision moves.

Thank you. I am trying to start an e-liquid mixing business (hence the title of this thread) and this robot (which is one of the two types of robots used) is part of the “production line”. again, I am right now working on making a video that better captures what this robot actually does.

That has what been the most time consuming aspect of the robot design. improving the accuracy and precision of the robot positioning, as the robot must stop under the nozzle of the syringe with a tolerance of ±5mm. And that is why I was considering to switch to stepper motors as they can do very precise moves but also they have lots of torque at low speed as opposed to dc motors which have no torque under a certain speed and do not have positional control. but that meant a major redesign of the robot and even maybe the need for a bigger battery pack. So I stuck with geared DC motors and fortunately was able to achieve the necessary accuracy and precision.

Pretty cool stuff.

Nice! Is that remote controlled or is it following a program? With the scales and the robotic arm I guess it’s going to be a mixing robot?

Right now I am controlling the robot raspberry pi using VNC from my laptop. but later the robot will get its commands from another software which pretty much controls and manages the whole thing which is being written using unity game engine. this software in turn gets the order from the website which is being developed by someone else.

yes it is a mixing robot (still a work in progress):

it is one of two robots. this one which fills bottles, and another robot for refilling the syringes. I have not started with the design of the refiller but it is almost identical to the filling robot, just with an extra actuator.

and sorry for the appalling camera work ![]()

Very nice project but I guess you’ll have to sell a lot of liquid before the time and investment pays back. I’ve just started playing with Arduinos. My programming skills are not great but there are a lot of projects where you can steal code snippets from and bend them into shape for your own ideas.

So you move the platform into position for a flavor and the robotic arm is pushing down on the syringes? My experience with syringes was that some flavors made the syringe kinda sticky and then it was hard to apply the correct pressure.

A friend of mine built a device to add the correct amount of chemicals into his sea water aquarium and he ended up using medical dosage pumps.

Or perhaps a linear stepper motor to push down?

I can imagine. I lost patience with a vacuuming robot a few years ago when the servos were playing up. I just gave up and bought a mop. But, the cats loved standing on it to minimise effort.

regarding the time and investment, you’re absolutely right. in hindsight it would have been better to start simple, with something more manual. But I guess I underestimated how much time it would take and overestimated my skills  but thankfully internet and YouTube tutorials have saved the day so far. And if there is one thing that worries me a lot is exactly that, am I investing all this time on a business idea that is fundamentally flawed.

but thankfully internet and YouTube tutorials have saved the day so far. And if there is one thing that worries me a lot is exactly that, am I investing all this time on a business idea that is fundamentally flawed.

On the other hand if I can make this work, I really hope that it will cut production costs enough so that I can offer products that are even cheaper than average e-liquid prices. on top of that 10% of the sale price will go to the recipe creator, so I thought more reason to keep costs down.

The platform doesn’t move. it is the robot that positions itself under each syringe. it does that using a light sensor unit under the robot. when it is “seeing” a black line, it means the robot is under the syringe at it will stop. these lines are also used to work out where the robot is. the lines are 60mm apart, so every time the robot crosses a line, it means it has moved 60mm.

I have also tried it with liquid in the syringe and it can still push the syringe down without problem. but I had to slow down the speed of the “hand” as if it does it too fast with liquid. the robot starts doing pull ups! the electro magnet is pretty strong.

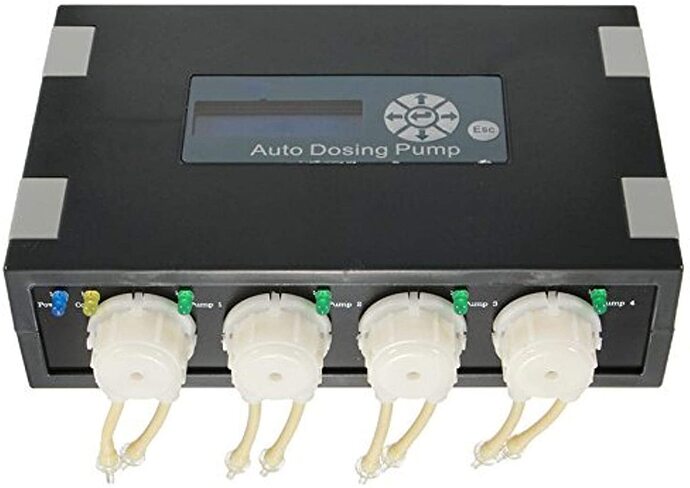

I hope you can get it to work! If the syringes don’t work you should really have a look at these dosing pumps. Easy to clean because it is basically just a rubber hose and a circular motion is pressing the liquid through the hose. It was also the best solution for precision.

Something like this:

The problem with this is that there are between 600 to 700 flavour ingredients that I think we’ll offer for mixing and so we will need 600 of these pumps and the cost would be too much. although for the VG and PG portion of each bottle, I’ll be using these pumps:

and for precision, the scale has a precision of 0.01 g which is precise enough (it will be 0.1% of a 10ml bottle, which is the smallest bottle size we’ll offer). Although getting the Pi Camera to read the values from the scale was a bit of a pain to implement as I couldn’t make the already existing and great OCR (optical character recognition) libraries to work for python on a Raspbian.

Fair enough, even home made pumps would cost a fortune for so many flavors. But if you had them it would work like a dream

That may be the case. But as @delltrapp pointed out, I think there will still be plenty of mod/pod vapers, definitely at least for the next few years. I have also looked at some market research reports for 2019 and 2020, and based on that I think what will happen is their number will decrease, but then it will plateau, with still quite a sizable proportion.

Anyways, your input is much appreciated. I will definitely have to look into it more.

@Ashkan I applaud your drive- and being so open with your ideas on ELR. I wish you the best of luck on your venture!!! Keep rocking dude!