I had a few people hit me up regarding how in the hell to test large(r) series without it turning into chaos. Well, hehe, it’s REAL EASY to.

I know people who have issues mixing up 5 mixes without issues, so 60+ flavors at a time, or even more, can rapidly get out of control.

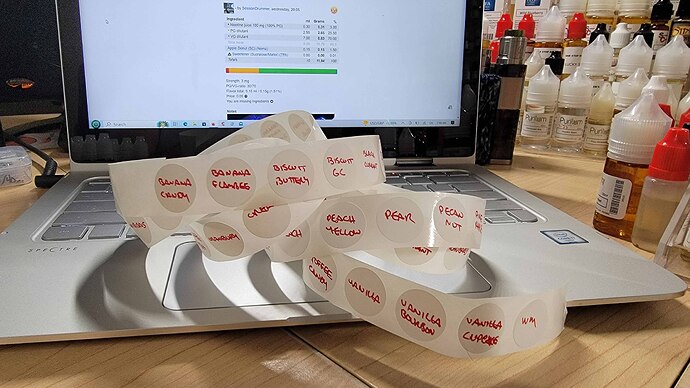

I always start out by counting how many I have to run, and make a list, then sanitize enough bottles for the run. I alphabetize the list for sanity, and hand write each flavor on round stickers.

Then I pull up the “recipe” and get the NIC levels, and fill ALL the bottles with their NIC first. With LOTS of bottles all over the place, it’s easy to spill and make a mess, so the NIC is done first, and capped and back into the freezer.

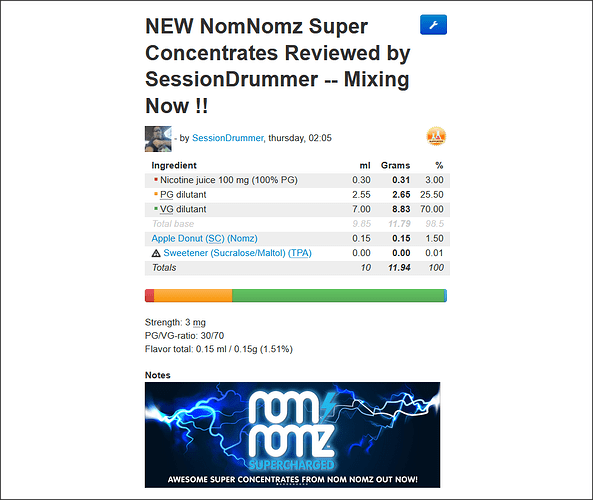

I think I hit 69 on this run, so that was 69 bottles with 0.31g of NIC, all ready for flavors and carrier. Then I load the individual flavors into each botte (0.15g in this case), and then hit 2.65g PG, and 8.83g VG. I leave THAT flavor on deck to VERIFY it before stickering the bottle. Then that flavor moves OFF deck, into the “done” box. Tipped, capped, shaken, and lined up in the waiting line.

You would be surprised how EASY it is, to run into REAL issues, especially on larger series. Just get a system, and never deviate, unless you find a BETTER one. Every time, all the time.

If you think mixing a few mixes is a PITA, try precision mixing 60+, without running over, spilling, etc. Any run overs get dumped, and added to the “do-over” list.

I think I ran through almost 500mg of VG, on this series, so if you are running a big series, make sure to have a big squeeze bottle, so you can just roll through them, uninterupted.

Any drops, drips, spills, or flavors on your fingers, stop immediately clean up before proceeding, or you can contaminate other bottles/flavors, etc.

Happy mixing !!!