Centrifuge Part 1

Filtration is a subject that is actively discussed in the NET DIY world. There are hundreds of posted threads regarding all manner of filtration, but none discuss the use of a Centrifuge. I thought I would try to begin to fill this gap, and make a few suggestions about the inclusion of this valuable tool into the bag of tricks of the experimentally inclined NET - DIYer.

I have created a post series about the use of Centrifuges in the world of DIY mixology, specifically in relation to DIY NET.

Post #1 - Centrifuges in DIY: a General Overview

WHAT IS THE DIFFERENCE BETWEEN MECHANICAL FILTRATION AND CENTRIFUGATION?:

CENTRIFUGE vrs MECHANICAL FILTRATION PROS AND CONS IN THE DIY WORLD:

WHAT TYPE OF CENTRIFUGE DO I NEED?:

WHERE DO I BUY A CENTRIFUGE ?:

I am not an expert in centrifuges, I am not a physicist, but I do have a background in industrial chemistry, so the subject matter is not entirely foreign to me, but please do not take my word for anything you see here regards this subject. All of the following is just my opinion,. It may or may not work for you. Your milage may vary. Continue to explore on your own and seek out expert advice. If you have knowledge, techniques, tips or tricks, that you wish to contribute to this subject then that is highly encouraged ! Just PM me and we will discuss the inclusion of new and valuable contributions.

DISCLAIMER PLEASE READ: All my posts are from the perspective of my personal intended target goal. That is: I have a very narrow perspective on DIY NET. It is for personal use only at small quantities. My target is usually no more than 60ml of concentrate and 10-15ml of finished vapeable juice per mix recipe using those concentrates. Please do not try to use my techniques to run a production shop. Before you begin: Please research safety of all chemistry, particularly the subject of Toxicity, using MSDS, pubchem, and CAS information. Please respect Centrifuges as they store tremendous kinetic energy. If you have a Centrifuge that makes unusual noise, wobbles, or overheats, or has other operational issues then immediately shut down the unit, and proceed no further until you can have the unit serviced.

WHAT IS THE DIFFERENCE BETWEEN MECHANICAL FILTRATION AND CENTRIFUGATION?:

Although the two processes can produce an end result that is very similar and accomplishes the same goal of a ‘clean’ extract for the DIYer, the two are actually very different. Mechanical filtration is blocking the unwanted material at a ‘doorway’ that is too small to allow the particle to pass. The advantage of this is that all particles of a certain size will be blocked regardless of their shape, weight, or composition. Therefore, with mechanical filtration, the resultant liquid will have a known good specification for its particulate content. The same can not be said for centrifugation. The downside of mechanical filtration is that filters clog with these unwanted particles and the flow rate slows down progressively as the filtration process proceeds.

Centrifugation produces a ‘clean’ supernatant fluid by the process of sedimentation. The force of gravity pulls on any object, including particles suspended in a liquid. Under gravity the particles slowly ‘fall’ through the liquid leaving above the ‘clean’ liquid that ‘floats’ on the top. This only works if the weight of the particles is greater than the specific gravity of the liquid. Lighter particles can float just as a helium balloon floats in the air. At a certain critical point it is impossible to extract very light particles using the technique of sedimentation, however mechanical filtration knows no such issue and can be used to ‘clean’ any and all particles regardless of their physical properties. Increasing centrifugation force can be used to progressively pull lighter and lighter particles, and some very sophisticated centrifuges can be use to separate even objects as light a bacterial and viruses. But this is out of the realm of the DIYer. For our purposes, using low power and low cost medical or lab grade bench centrifuges, the differences between the end result of the two processes can be considered almost identical and acceptable for our purposes if we accept that we do not know exactly “how clean” the result is from centrifugation, whereas if using lab grade mechanical filtration we can more accurately make a statement about the result.

CENTRIFUGE vrs MECHANICAL FILTRATION PROS AND CONS IN THE DIY WORLD:

There are commonly several filtration steps in the DIY NET process. In the mechanical filtration world, the earlier steps commonly use re-purposed coffee filters and/or standard Quantitative lab filter paper. The ‘finish filter stage’ commonly uses specialized lab grade 2 micron or smaller pore size filter paper.

The cons across all these steps of mechanical filtration is cost, product loss and time. The pros for centrifugation is just these points in reverse. It is faster, cheaper, and almost lossless.

High flow rate micron pore filter paper or fritted borosilicate glass is very expensive. A pack of 1 micron lab filter paper is typically about $100US. There is no such cost associated with the centrifuge. If you choose to use disposable tubes, the cost is trivial. Disposable Tubes can be had for about $10 /per 100pcs. If you use glass tubes they can be washed and reused and the cost becomes almost Zero over time.

One of the biggest cons of mechanical filtration systems is the loss of product in each filtration step. It is not uncommon to use multi filtration steps, first to separate the feedstock maceration from the crude juice extract, then progressive steps thru 20 micron filters (typically repurposed ‘coffee filters’), then through a 10 micro step, then a 2 micron step, and sometimes even further. At each step there can be significant product loss. There is no such product loss in centrifugation.

Another Con of mechanical filtration is the time required. If you do not have a vacuum filtration setup then gravity filtration can take 24hrs or longer per 60m per each filtration step. It can take days of your time to use a mechanical filtration process. Even a simple lab bench top Centrifuge running at 2500RPM can accomplish the same steps in a matter of minutes or at the most a few hours.

The cost of mechanical power driven vacuum filtration glassware and pumps can be very high, easily exceeding the cost of a centrifuge by several times.

Another possible con of using mechanical filtration deals with the largely unexplored possibility that extreme sub micron filtration might be taking unseen flavor components out of the NET. It has been reported anecdotally that some experimenters have noticed that using multiple stage and or very high performance mechanical filtration through lab grade filters that are at or less than 1 micron have lightened or otherwise altered the flavor profile of some NETs. This subject calls for a diligent and controlled testing protocol to get to the bottom of this subject. I have long been an advocate of testing the use of specialized homogenizers to marry all flavor components of of NETS. I have it on my personal ‘to-do’ list to obtain the necessary equipment to explore the subject of homogenization. Because of the very high cost of that equipment those experiments have not yet been carried out. This is one of the differences between spinning in centrifuges vrs mechanical filtering that should be explored. The right thing to do is to run a series of test protocols with a known extract, and look at all these possible issues. The human taste and nose are very sensitive tools and I think we might be very surprised how much damage we are doing to tNETs with ulta-micon mechanical filtering. It is worth thinking about. From a lab science perspective, to be a responsible researcher, tests absolutely need to be done. Just to go blindly ahead with all this filtering without really having lab results to back up what we are doing is foolish.

One con of using a centrifuge is that it is a high precision device that may require maintenance over time. As with all such devices the possibility of a failure is always present. Repairing a failed device will add to the cost of using the technique. In contrast, mechanical filtration is a very robust technique with minimal failure modes.

Another con of using centrifuges is that they are not for everyone. What I mean by that is that in the hands of certain persons they can be dangerous. Before you decide to give the centrifuge a try for your DIY you should make a personal appraisal of how comfortable you are, and your skill levels using this type of equipment. A good example analogy is: if you are comfortable using a Skill Saw to cut lumber, and you understand how to handle and use sharp power driven blades, then you should be fine with a centrifuge. If the thought of operating a radial arm saw makes you nervous, then you best stick with filter paper. Be honest with yourself. Do not get in over your head.

WHAT TYPE OF CENTRIFUGE DO I NEED?:

There are an endless variety of designs in the very vast world of centrifuges. To oversimplify and narrow things down we will broadly classify them as tabletop type versus everything else such as floor mounted or continuous industrial process types. You will be looking for a small lab or medical grade table top device. Speeds and power are generally divided into low speed lab and medical, then high speed types, then ultra centrifuges. The price goes up dramatically for higher speed centrifuges, so a low speed medical unit is fine for our purposes. It is worth noting that high speed centrifuges require specialized and very expensive product sample tubes, as well as advanced training on their use and safety. You will be fine with any centrifuge that runs at a minimum of 2500 RPM. Preferable would be with units that run close to 4000. Units over 6500 are available as table top units and that should be the maximum necessary for hobby level NET use. Units that run over 6500 should probably be avoided, unless you have specific previous training and experience in their use.

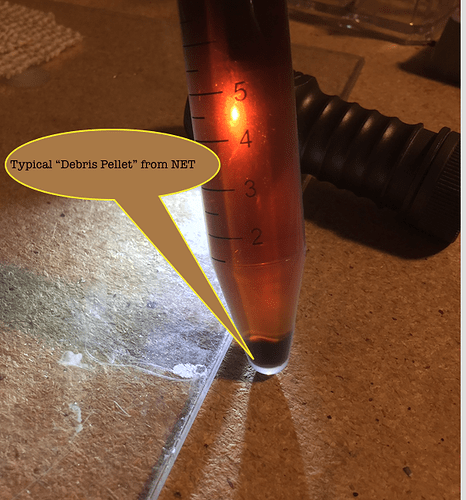

When deciding about speed of a prospective and suitable unit, it is commonly misunderstood that RPM of the rotor is the determining factor in centrifuge of performance. In fact it is the combination of dwell time on the sample and the increase in the multiplier of gravitational force over time that determines how well you will separate out your vape fluid. As an example, centrifugation of a sample at 5,000 RPM in a microcentrifuge that has a rotor with a radius of 7 cm will deliver a centrifugal force of 1,957 × g. If the radius is smaller then the force drops accordingly. Centrifugation speed (force) and time often are not critical factors in routine sample handling procedures involving a bench-top centrifuge. Usually, as long as speed and time are sufficient to ensure that cells, debris or resin are pelleted effectively, it does not matter if the speed is faster or the time longer than necessary. For this reason, many of our protocols for vape liquid clearing will not specify a particular centrifugal force to be applied but instead indicate some general guideline such as “centrifuge at high speed for 60 minutes.” In our case, we will just centrifuge for enough time to form the “pellet” at the bottom of our tubes and stop when we deem that the supernatant fluid is clear and clean enough for our vaping purposes. See the paragraph at the start of this post for discussion of the difference in known good particle level in centrifugation vrs mechanical filtration.

Further to decide about, there are several rotor types or heads to choose from. These heads are generally divided between two major types: swinging buckets/heads or fixed rotor. For our vaping purposes either head design is OK. There is a slight benefit to getting a swinging head design, and I recommend if you have the choice you choose the swinging bucket type. See this excellent page for a nice description of why the swinging head design is better for our purposes. Many rotors allow for the use of various replaceable and interchangeable bucket carriers. Here is a little You Tube video showing some of the ones that would be very applicable for spinning down vape liquid. https://m.youtube.com/watch?v=9yisjvmj57Y . Typically you will want a rotor and carrier that uses the very standard and readily available 15ml and the 50 ml tubes. Some heads accept so-called ‘micro centrifuge tubes’ but their available tube volume is very low for our purposes at around 5ml per tube. You will have to be aware of the number of tubes that the head accepts. Typically you can find units that accepts 4 x 50 ml tubes for a total capacity in one run of 200ml… Another typical head design accepts 6 x 15ml tubes for a total capacity of 90 mls. These make fine choices for hobby level NET experimentation.

WHERE DO I BUY A CENTRIFUGE ?:

Unless you recently won your State Lotto, you will be looking in the used market. Since table top centrifuges are ubiquitous in the medical and university lab environment, there are many that eventually hit the used market place. You will have no problem finding a massive available number for possible purchase. The challenge is three fold. First you must find one that meet your needs as far as speed and tube size. Second you will have to find a reliable seller that will unconditionally guarantee the unit is currently working to specifications and is not damaged or in need of repair. A cooperative seller with a 100% satisfaction guarantee policy is important. Because of parts supply and replacement cost issues on older centrifuges that may no longer be supported by the original manufacturer you will want only a fully working unit.

The third and possibly most important consideration is shipping of the unit. Just because the units are table top in class do not be fooled about the bulk and weight of these units. I have a Fisher Scientific Marathon6K unit that weighs almost 100 lbs and measures over 20” on a side. These are almost impossible to ship in a cardboard box in the UPS system that exposes the delicate and fragile precision units to extreme handling abuse. The right way to ship these units is strapped to a pallet and handled by a freight carrier that understands how to transport lab equipment. I strongly suggest that you search for a used unit that is within driving distance to your location, and then you can perform an on site inspection to verify the working condition of the unit, and then you can transport the unit yourself, giving it the necessary care required during transport.

You may want to start out your experimentation with centrifuges by using one of the “oldies but goodies”. They are far less expensive, easier to repair and transport and will not commit you to jumping into the deep end of the swimming pool right off the bat. Modern designs use micro processor control boards and many internal sensors and elaborate drive systems. Older designs are simply a rotor head on a shaft with direct drive by a motor. They are very bullet proof over the long haul and last for years. A surprising benefit of these old designs is that the enclosure chamber for the rotors were simple designs that were not insulated. This makes them noisy, which is not really an issue, but it has an interesting side benefit for their use in NET. Because of the older crude design the chamber will heat up during use as it is not insulated from the drive motor. I have a very old ICE table top unit that heats up to about 90F during use. This conveniently heats tubes with the PG extraction during a spin. Because a centrifuge is operating on the principle of relative weight of the particles against the specific gravity of the carrier liquid, it is convenient that the PG is a little on the warm side, therefore lowering the viscosity and speeding the sedimentation process.

There is a very active and ever changing market of offerings on eBay. I picked up the old but very serviceable ICE unit there for $40 including shipping, so basically the seller gave me the unit for free as he paid the shipping. I picked up a Marathon6K for $175 but I paid the shipping. You can search Craigslist, and other local want ads… Also there are professional commercial re sellers of lab equipment, but I have not had good luck with them, as the prices are usually very high, and the units are usually too specialized for my use. Also, it is more work and more of a long shot, but if you have a local University or College you might check with their purchasing department and inquire if they have items that they might be cycling out of service.

But in all cases, remember, the rule is to determine that you are getting a known good currently working unit, and assure that the shipping will work for what is large and heavy but yet very delicate lab grade equipment.

My guess would be, not much… but, something has to be in that “pellet”… just curious if that “something” would be molecules of flavor?

My guess would be, not much… but, something has to be in that “pellet”… just curious if that “something” would be molecules of flavor?