Continuing the discussion from N.E.T Creations and Reviews (Naturally Extracted Tobaccos or Teas):

Today I started my second attempt at creating N.E.T. flavors. I’m strictly in an experimental phase, but if the results are positive, I’ll be at it full bore. I purchased a very good slow cooker today, which is vital for this type of extraction.

This particular slow cooker comes with a probe for temperature accuracy.

This is what’s needed for the first part of the extraction:

PGA 190 Proof (95% alcohol)

Tobacco

Heat resistant glass container

lid or in my case rubber stoppers

Preheated slow cooker or a thermostatically controlled hot plate.

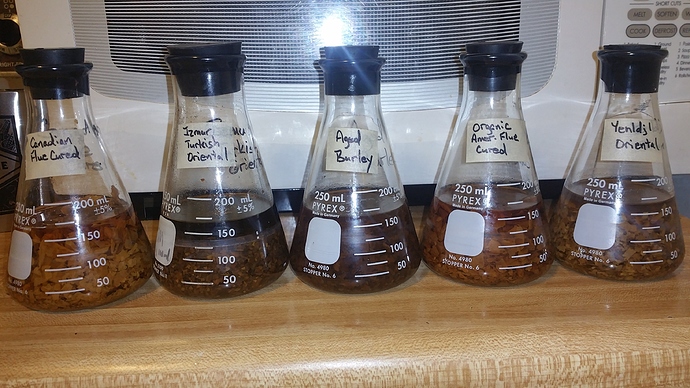

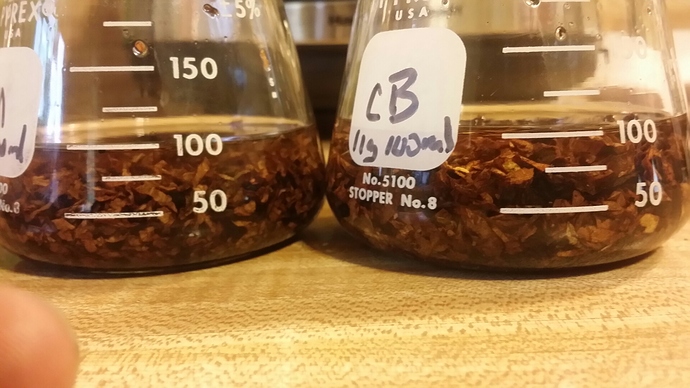

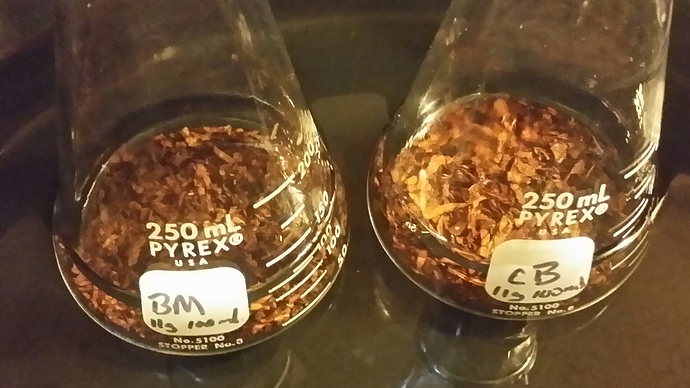

I first gathered and weighed my tobacco. I’m trying to run identical test on both tobacco brands. I used 11 grams each.

I then loaded the tobacco in my flasks and filled with PGA until slightly past submersion. They both were 100 mls.

Now I capped/plugged the flasks lightly to avoid any pressure buildup, (but not too lightly to avoid PGA evaporation). I put both flask in the preheated slow cooker @ 160 degrees for twelve hours maintaining a water level equivalent to the PGA level in the flask.

After the 12 hr. heated extraction there was little to no loss of liquid and my water level was even with the extraction level through the entire process.

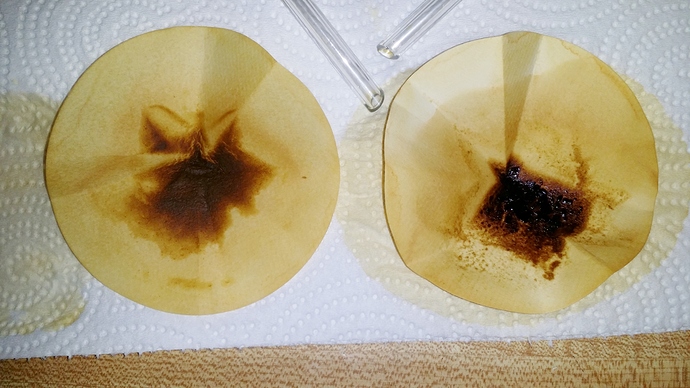

My next step is to strain this mixture through coffee filters.

I also squeezed the leftover tobacco and filter to get the last of my mixture.

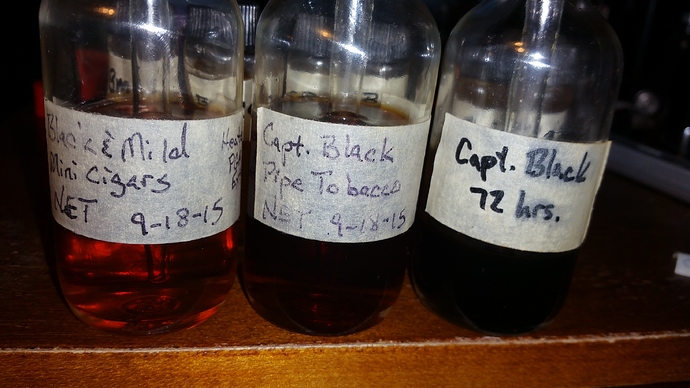

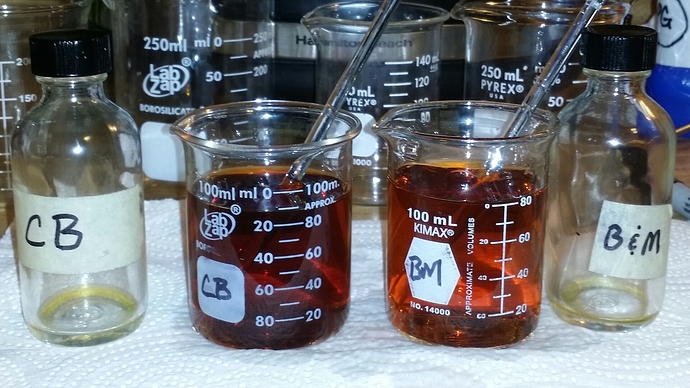

I bottled and labelled my extractions and placed them in the freezer for 2 days. The waxes and oils pulled from the tobacco will stratify at the bottom of the container.

This was filtered after the freeze portion of this process. If you only use coffee filters for your NET and skip this stage, this is what your are vaping. This may be the most important step of the entire process.

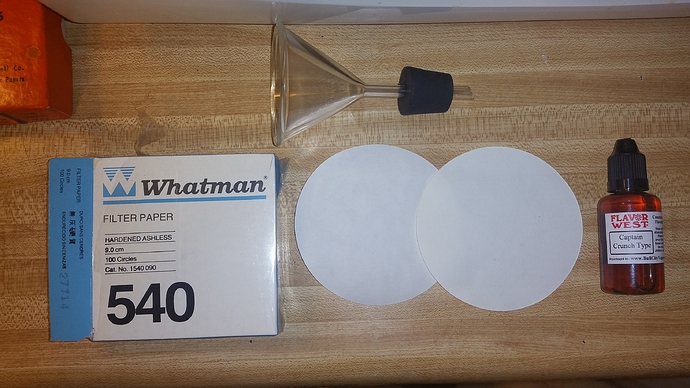

Filtered through 1 micron filter paper.

I will continue this step until nothing is retained in the filter.

After 2 frozen filter cycles though a 1 micron filter, nothing is left to filter. It’s now ready for the final stage…reduction and transfer to pg.

This stage is accomplished by mixing the extraction 2 to 1 with pg and heating to evaporate the pga.

I have approximately 60 mls of extracted tobacco flavor in pga. I pour 30 mls pg into a beaker.

Then I pour the remaining extraction into the pg and stir for the heated evaporation/reduction cycle. I’ll heat this mixture until it’s reduced to approximately 30 mls. This step has a two-fold purpose… concentrating the final product and eliminating the pga.

I completed the tranfer and reduction stage this morning. I have a final NET of 40 to 50 mils each product. I did one final filtering before bottling my final NET. I’m gonna let these steep for a week before testing to let the flavors bond with pg. They both smell awesome and much stronger than the vendor tobacco flavors. I will report my finding once I make a mix.

See ya in a week or so with updates!

See ya in a week or so with updates!