I just built an identical SS build on an RDA that I had in my TF-R2. This time it popped into Watts mode about 3 times but after setting it to TC again each time it finally stayed. I’ve vaped it dry a few times and still holding steady. This is puzzling the hell out of me because I have no doubt whatsoever that in the tank I had no shorts, no loose connection and no contacting coils. So aside from the annoyance of having to return the mod to TC a few times at first it would appear that my mod will indeed work in SS TC mode. Scratching my f*@$*# head.

Do you have another TC mod? I’m curious to know what it reads on it vs the cube?

Also is it possible that the small amounts of Ni in SS could have an effect on the cube? I guess this would be lumped into what effects different grades have?

They both read 0.14 watts. As I said before my ohm meter died so I can’t verify on that.

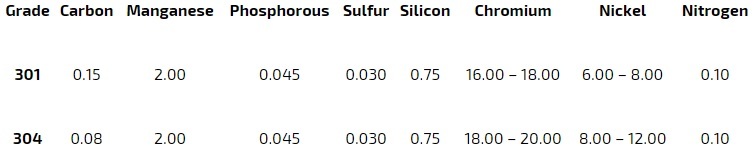

I do think the amount of other metals would indeed affect the coil’s temperature coefficient. Isn’t the proportions of metals in the alloy what makes it 316 vs 318 vs whatever? Personally I think just making the mod capable of working in TC mode with different metals is not enough if there is a big difference in different grades’ TCoR. So rather than just setting for SS, set for SS(316) or SS(317) and so on. But perhaps the coefficient isn’t enough to make that big a difference, I just don’t know.

What other mods are set up for SS/TC?

Crown stock 0.25o SS coils, yes ![]() Works perfectly on my XCube 2, but Koopor Plus, I have to adjust ohms…

Works perfectly on my XCube 2, but Koopor Plus, I have to adjust ohms…

Mine does that when it reads initial ohms too high…

To be honest my knowledge of metal composition is nill…except for…

18-8: 300 series stainless steel having approximately (not exactly) 18% chromium and 8% nickel. The term “18-8” is used interchangeably to characterize fittings made of 302, 302HQ, 303, 304, 305, 384, XM7, and other variables of these grades with close chemical compositions. There is little overall difference in corrosion resistance among the “18-8” types, but slight differences in chemical composition do make certain grades more resistant than others do against particular chemicals or atmospheres. “18-8” has superior corrosion resistance to 400 series stainless, is generally nonmagnetic, and is hardenable only by cold working.

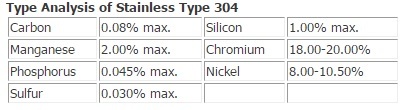

304: The basic alloy. Type 304 (18-8) is an austenitic steel possessing a minimum of 18% chromium and 8% nickel, combined with a maximum of 0.08% carbon. It is a nonmagnetic steel which cannot be hardened by heat treatment, but instead. must be cold worked to obtain higher tensile strengths.

The 18% minimum chromium content provides corrosion and oxidation resistance. The alloy’s metallurgical characteristics are established primarily by the nickel content (8% mm.), which also extends resistance to corrosion caused by reducing chemicals. Carbon, a necessity of mixed benefit, is held at a level (0.08% max.) that is satisfactory for most service applications.

The stainless alloy resists most oxidizing acids and can withstand all ordinary rusting. HOWEVER, IT WILL TARNISH. It is immune to foodstuffs, sterilizing solutions, most of the organic chemicals and dyestuffs, and a wide variety of inorganic chemicals. Type 304, or one of its modifications, is the material specified more than 50% of the time whenever a stainless steel is used.

Because of its ability to withstand the corrosive action of various acids found in fruits, meats, milk, and vegetables, Type 304 is used for sinks, tabletops, coffee urns, stoves, refrigerators, milk and cream dispensers, and steam tables. It is also used in numerous other utensils such as cooking appliances, pots, pans, and flatware.

Type 304 is especially suited for all types of dairy equipment - milking machines, containers, homogenizers, sterilizers, and storage and hauling tanks, including piping, valves, milk trucks and railroad cars. This 18-8 alloy is equally serviceable in the brewing industry where it is used in pipelines, yeast pans, fermentation vats, storage and railway cars, etc. The citrus and fruit juice industry also uses Type 304 for all their handling, crushing, preparation, storage and hauling equipment.

In those food processing applications such as in mills, bakeries, and slaughter and packing houses, all metal equipment exposed to animal and vegetable oils, fats, and acids is manufactured from Type 304.

Type 304 is also used for the dye tanks, pipelines buckets, dippers, etc. that come in contact with the lormic, acetic, and other organic acids used in the dyeing industry.

In the marine environment, because of it slightly higher strength and wear resistance than type 316 it is also used for nuts, bolts, screws, and other fasteners. It is also used for springs, cogs, and other components where both wear and corrosion resistance is needed.

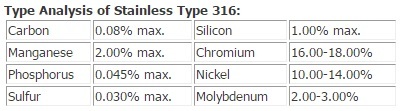

316: For severe environments. Of course, there are many industrial processes that require a higher level of resistance to corrosion than Type 304 can offer. For these applications, Type 316 is the answer.

Type 316 is also austenitic, non-magnetic, and thermally nonhardenable stainless steel like Type 304. The carbon content is held to 0.08% maximum, while the nickel content is increased slightly. What distinguishes Type 316 from Type 304 is the addition of molybdenum up to a maximum of 3%.

Molybdenum increases the corrosion resistance of this chromium-nickel alloy to withstand attack by many industrial chemicals and solvents, and, in particular, inhibits pitting caused by chlorides. As such, molybdenum is one of the single most useful alloying additives in the fight against corrosion.

By virtue of the molybdenum addition, Type 316 can withstand corrosive attack by sodium and calcium brines, hypochlorite solutions, phosphoric acid; and the sulfite liquors and sulfurous acids used in the paper pulp industry. This alloy, therefore, is specified for industrial equipment that handles the corrosive process chemicals used to produce inks, rayons, photographic chemicals, paper, textiles, bleaches, and rubber. Type 316 is also used extensively for surgical implants within the hostile environment of the body.

Type 316 is the main stainless used in the marine environment, with the exception of fasteners and other items where strength and wear resistance are needed, then Type 304 (18-8) is typically used.

Corrosion Resistance

Don’t let corrosion happen to your custom wire baskets! Most stainless steel alloys have good or excellent resistance to corrosion in normal conditions. Stainless steel alloys tend to possess a strong, but thin, layer of oxide that prevents rusting, hence the name “stainless” steel.

In mildly corrosive environments at normal ambient temperatures, the corrosion resistance of grade 301 and grade 304 stainless isn’t very different. Generally speaking, grade 301 tends to be a little less corrosion resistant than grade 304 because the 301 alloy has a lower chromium content and a higher level of carbon.

At higher temperatures, the difference in corrosion resistance is more pronounced.

For example, if you were to weld or laser-cut a piece of 301 stainless steel, you would be more likely to see signs of corrosion in the heat-affected zones than you would in a piece of 304 alloy treated in the same way. This is because of chromium carbide precipitation, which depletes the chromium in the heat-affected areas.

Other Types of Stainless and grades:

Austenitic:

Type 301contains less chromium and nickel than 302 for more work hardening.

Type 302 is the basic type of the 300 series, 18% chromium— 8% nickel group. It is the renowned 188

Stainless and is the most widely used of the chromium nickel stainless and heat resisting steels.

Type 303 contains added phosphorus and sulfur for better machining characteristics.Corrosion resistance is slightly less than 302/304.

Type 303Se contains Se and P added to improve machinability.

Type 305 has increased nickel to lower work hardening properties.

Type 309 309S have added chromium and nickel for more corrosion resistance and high temperature scaling resistance. 309S contains less carbon to minimize carbide precipitation.

Type 310 310S have higher nickel content than 309309Sto further increase scaling resistance.310S contains less carbon than 310 to minimize carbide precipitation.

Type 321 contains titanium to tie up the carbon and avoid chromium carbide precipitation in welding.

Type 330 ultra high nickel content provides best corrosion resistance to most furnace atmospheres. This grade has low coefficient of expansion, excellent ductility and high strength.

Type 347 – 348 have columbium tantalum added to tie up the carbon and avoid chromium carbide precipitation in welding. Use for temperatures from 800to 1650 degrees F.

Ferritic:

Type 405 contains 12% chromium with aluminum added to prevent hardening.

Type 430 is the basic type in the ferritic group, possessing good ductility and excellent resistance to atmospheric corrosion. Its scaling resistance is higher than 302 in intermittent service, somewhat lower in continuous use.

Type 430F 430Se have sulfur and selenium (respectively) added for increased machinability.

Type 442 has added chromium for improved resistance to scaling.

Type 446 has still higher chromium content (27%) for added scaling resistance and is highest of the standard straight chromium types. Alloys with over 30% chromium become too brittle to process.

Martensitic:

Type 410 is the basic Martensitic type. It is the general purpose corrosion and heat resisting chromium stainless steel. It can be hardened by thermal treatment to a wide range of mechanical properties. It can be annealed soft for cold drawing and forming. This grade is always magnetic.

Type 403 is a special high quality steel made for blades and buckets for steam turbine and jetengine compressors. This grade is eminently suited for very highly stressed parts. This material is magnetic in all conditions.

Type 416 416Se

are modifications of Type 410, being the free machining, nonseizing, nongalling alloys. These properties are obtained by the addition of sulfur or selenium to Type 410.This is a heat treatable grade with corrosion resistance and other characteristics closely approaching those of Type 410.

Type 420 is a chromium stainless steel capable of heat treatment to a maximum hardness of approximately 500 Brinell. It has a maximum corrosion resistance only in the fully hardened condition. Type 420 is magnetic in all conditions.

Type 431 is a nickel bearing (1.252.00%)chromium stainless steel which may be heat treated to high mechanical properties. It is magnetic in all conditions of use. It has superior corrosion resistance to Types 410, 416, 420, 430 and 440 stainless steels.

Type 440C is the stainless steel that can be heat treated to the highest hardness of any of the others

Yes, it’s easy to admit that not everyone fully understands the XCube and honestly I do blame both the mod and the manufacturer for this. I’m a firm believer that this mod should not require you to be tech savvy to operate in temp mode. Where on the box does it state this requirement? They are selling to the general public and that means that the general public should be able to operate it without a engineering degree. No other temp control mod I know of requires this much tech to get it working. It took @Pro_Vapes 3 days to get his first XCube working. Being he is most likely the best we got here on ELR what chance does the average vaper have of getting this mod working correctly. No one should have to spend days or even weeks gathering information and help to get a mod to work in TC mode. The joke is Smok and few are laughing…

This could be said about a lot of gadgets. Cameras, computer equipment…for that matter computer programs. They sell Excel and Photo Shop to whoever wants it too. Just because it’s not marketed as a device that is not plug and play, click and shoot, whatever - does that mean it should not be sold to the public? Nah, people should do a little homework before buying things. Like if I go buy a new TC mod and don’t verify it is designed to work with Ti wire before buying, I have only myself to blame. Anyway, I’m standing down now. I have a feeling that many well-meaning statements have been misinterpreted and tempers may be flaring due to folks feeling they have been taken for a ride with their purchase. I really hope some update comes out that fixes issue with the Android app and the device that people are having.

Comparison to a computer, none. Software, no comparison. Thank Goodness! It’s even difficult to compare to a camera since the needed functionality of a camera is so much more. Why not compare with other TC mods. Why is it that other TC mods don’t take days to set up? Why is it left to the user to play with the settings that most don’t understand and quite frankly should have been automatically detected and set for them. If other TC mod manufacturers can do it, why can’t Smok with the XCube? That’s my question…

Excellent point…that would put them ahead of the rest, IF it had worked…

The only relevant info needed for Steam Engine to create a working CSV file for the DNA 200 is the wire type and gauge, the build doesn’t matter as long you don’t mix wire types. It doesn’t even matter if you have single or dual coils. Most TC mod do automatically set things for just by selecting wire type and locking in your ohms. Smok did give the user more control but the sporadic nature of Smok software make user control null. If the software can’t accurately read your ohms then everything from that point is inaccurate.

I have two profiles on my DNA 200s… 22g and .5mm and they work with all my tanks and drippers regardless of the build, ID, single or dual coils, as long as they are built with Ti grade 1.

When I first read this I thought…man he’s doing something besides vaping ![]() Why? Well when I’ve gone in to set up my wires I’ve been watching the blue section as the results change. Here is two clips - the first is the default when you land on the Wire /Wizard page and switch to Titanium. The second is changing to Titanium only entering the wire gauge and other info.

Why? Well when I’ve gone in to set up my wires I’ve been watching the blue section as the results change. Here is two clips - the first is the default when you land on the Wire /Wizard page and switch to Titanium. The second is changing to Titanium only entering the wire gauge and other info.

As you can see there are quite a few changes in the blue results section. This had me scratching my head because I knew you had to know all about this. So I decided to download the CSV sheets and compare. Damn, even with different wire gauges, leg length, spacing, the spreadsheets were identical!

What I found more amazing, and I’m embarrassed to say I never looked at it before, is there appears to be only two categories of values to the entire CSV file -

Just when I thought I was getting a handle on all this. So unless there is something hidden in the CSV file and I’ve just not found it, it would appear that all you need to do using Steam Engine is to go to the Wire Wizard, change to Titanium and download the file. Yes? Geez.

Well, unless I am mistaken all changes for a given material (to first order) should really just offset the curve, not change its shape. So the mod could just read the cold resistance of the installed coil and apply the offset to the loaded curve and go.

I’d need to look into it a little more, but it seems plausible. I mean TCoR does have a curve to it typically over wide temperature ranges, but I think most materials should be linear around vaping temps.

haha, this thread isn’t even bothering with the cube anymore.

hey @SthrnMixer, I’d consider sending you my mod. Tell me though, does your TC work on like a 1s interval where you get a big cloud of vapor wait one another cloud in time with the screen flashing temp protect? I also have a Smok Ti dual coil unused and could build the -r2 to the same resistance to see if both suck in the same way…but I’d really rather mix juice and never think of that thing again.

so ive had the xcube2 for a while and about a month ago it needed the first upgrade but when I tried im experiencing every problem there is. I used all your links but when I go to connect it it says invalid chip id or wont connect at all please help im tired of using crappy kangertech

Damn, sorry to hear this. I haven’t used my xcubes for almost a year now, so I really don’t remember the interface or the details. Unfortunately I am not home right now, so I can’t pull it back out and refresh my memory.

I assume you are using the old/original installer and not the newer one? I vaguely remember people having this issue using their newer updater software but never the old one.

Just to take a stab in the dark, have you tried rolling it back to the first version/os?

Had the same issue, just use the latest version of this tool from the smok website and then use the hex files contained within this thread. Worked for me and now my Xcube II appears to be behaving itself!

PS many thanks to OP for providing the files.

hey, do you maybe have the newer hex versions ? the 1.098 dosent works for me… i always get the error message dont abuse protects… have you maybe got 1.095 - 1.097 ?

Hey. Sorry i’m reviving this old thread. I Just recently got my hands on an old x cube 2 with firmware version 1.092. can you update the link with the different firmware updates? The one you have posted doesn’t work anymore.

Cheers Nicolaj

I no longer have them on the drive, but if you pm me an email address, I’ll be more than happy to send ya what I have.