The deck would be the same shape, and of course the chimney would have to snap in place similar to the Crown.

Edit: But it would probably require a screw like the Kanger.

The deck would be the same shape, and of course the chimney would have to snap in place similar to the Crown.

Edit: But it would probably require a screw like the Kanger.

I don’t like the look of them but I like the way the air intake works. I’m not a fan of moving metal parts so in that regard I do like the bands.

Now that would be incredibly cool ![]() hehe

hehe

I totally agree with @SthrnMixer and @death

Just make sure it would suit everyones needs. Plus ohm, Sub ohm, screw in pre made coils, single coil build deck, dual coil build deck, MTL,(mouth to lung hit) DLH,(direct lung hit) and don’t forget it must work great with TC(temperature control) O ya it must be top fill with no leaking, easy to adjust air flow. And this list could go on forever but you get the idea The Perfect Tank to proudly wear the ELR name.

No, no no! ![]()

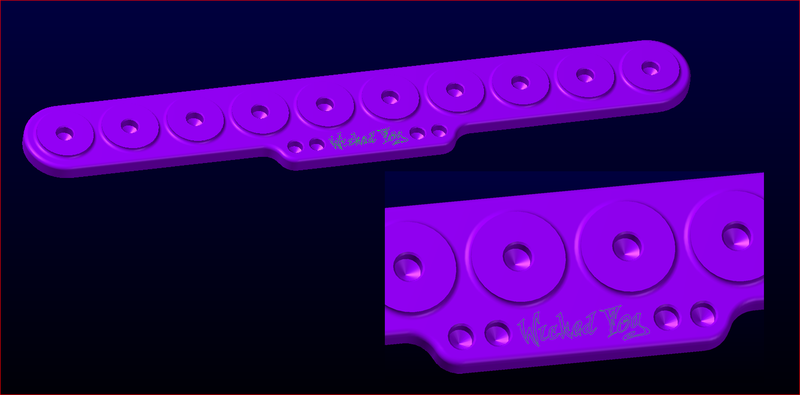

I knew this was going to come up. Believe me, I have designs going around in my head all the time for things. It’s just a matter of reverse engineering some tanks to get them modeled up to be able to really see how they work, and come up with a design based off of that. Some of you may have seen the atty holder I have in the works. This is my first vapor related design and is still a work in progress.

I like it!!!

Ok, here’s all you need to do for reverse engineering.

No RTA - make an RDTA just like the Aromamizer except rather than the funnel top with the awkward drip tip connector make it flat like the Subtank Mini with a fill slot like the Lemo 2.

RDA - not my main focus in life but a velocity style deck is a must! My idea is rotating/threaded ring with 3.5mm SS tubing for focusing air intake directly on coils. These wouldn’t go in perfectly horizontal but rather at an angle like 35deg or so, angled down and of course higher than the coil. It wouldn’t need to be long at all, just long enough to direct and focus the air.

That would require a machine similar to a Mazak Integrex, which 99.9% of machine shops can’t afford. I suppose a fixture could be made to hold the upper portion of the tank in at the proper angles to machine the holes. But it wouldn’t be too terribly difficult. The tank would just have to have a feature machined into it to align it on the fixture. I don’t have a Lemo 2. Is that a tank I should get?

If you like single coil tanks then yes, the Lemo 2 is fantastic. I traded an Ohmega for it and glad I did. Then I had a buddy send me an Ohmega  Like a Christmas all the time.

Like a Christmas all the time.

The Dark Horse RDA (not known as a flavor RDA) uses a ring for air intake. Maybe look at that design . The ring sits on the main chamber and then the top screws down over it. Pressure sets the ring in place and prevents it moving.

Oh hell yeah, that fill slot on the Lemo 2 is awesome. No problems with pressure build up like the Ohmega and the Crown when you screw the top back on. The TFV4 is a somewhat good design, but clunky. I get so tired of the gasket pulling out when I fill it and remove the bottle. Plus it’s messy as hell.

We need to start a new thread in the hardware section

The one and only complaint I have with this dripper is no Single Coil option. I have modified mine by closing off the air holes on one side to make it a single coil dripper. That is my flavor testing device as I am not really a fan of drippers

Right? I was thinking the same thing. We all know what works and what doesn’t. It would be so cool to have an ELR RDA or tank…just to have the Chinese copy it. LOL

Imitation is the highest form of flattery! Well, when it comes to the Chinese it seems they’ll copy anything ![]()

Also the ELR logo (the two flasks) needs to be etched into the sides. www.e-liquid-recipes.com on the other side (bottom section) and something on the top section or bottom next to the 510 etched to say LordVapor.

Ok made it here had to go do something. I love the velocity deck but I am still a single coil user so I had to modify mine to work BETTER for single coil builds.

Now onto the tank design. I am liking all of the ideas so far but I still think a tank capable of single or dual coil builds with adjustable air flow from fully closed off to wide open enough for good direct lung hits would set this tank apart from all others. Also an easy deck to build and top fill that does not leak when filling.

I only own the original Lemo and 1 kayfun 3.1 so I can not give you good tank designs ideas in comparison to other tanks out there.

RTA…Refillable Tank Atomizer…A refill port accessible without the need to remove the entire tank assembly from your mod …Air flow control, again, without the need to remove the tank assembly from the mod…smooth action firm adjustability from open to close…operable during the hit, as well…Actually I am in the process of designing some tweaks on my LemoDrop…and these are the two biggest issues with that RTA…A shame, because it’s an easy build with great flavor…

After thinking a bit if you were to use the velocity style deck and get air from the bottom I guess if there was a way to block off the air hole and possibly the juice channels on one side that would accomplish the single and dual coil aspect. But probably an engineering and manufacturing nightmare unless there was a way to do 2 decks one single coil and one dual coil and make them easy to swap out.

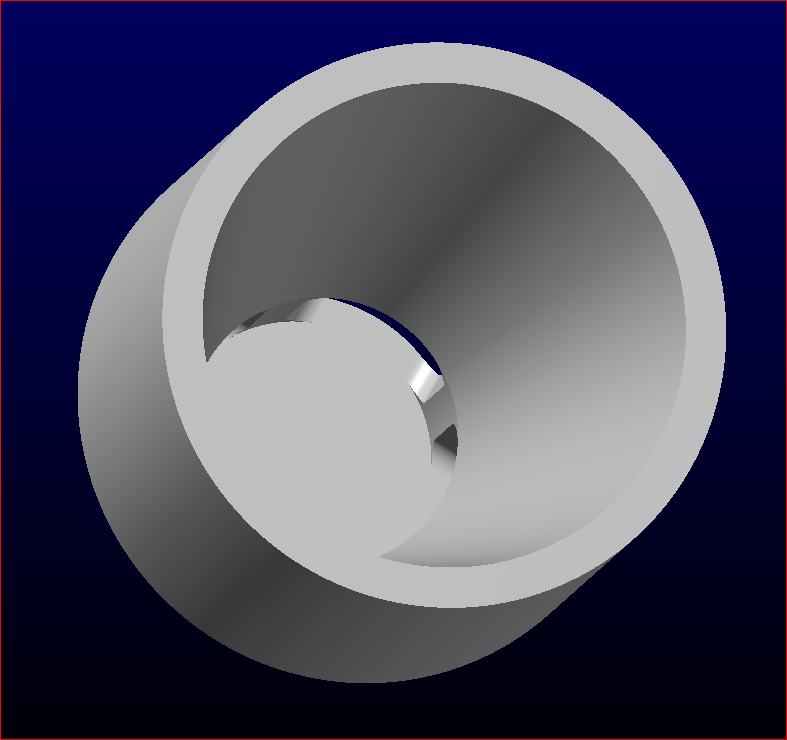

I have started reverse engineering the Aromamizer just to get a design to start working with. I have to wait to suck the rest of the juice out of it to get much farther LOL. I managed to finish the drip tip though…

I dont have an aramorizer so I cant compare, but I am not a hug fan of 510 drip tips, sorry. I like a big fat delrin chimney and I have not seen one of those that incorporates the spatter shield. . .would take a ton of real estate. I like a delrin chimney because I’ve nearly chipped a tooth several times on the bumpy roads where I live and also out of clumsiness. The big chimneys really seem to bring the flavor. . .I wish someone would just design a new huge cap for the TFV4 even. . .drive out the pin and add one that sticks with an o-ring and includes a seal to block off the juice port.

RE the velocity deck. I feel it sinks a rather large amount of heat from the coils. It is wonderful to build, but I think it makes the atty a bit of a pig on power. I like the Ohm ega design, but would prefer set screws and for the holes to sit closer to the air inlets.

I think creating air turbulence around the coil, preferably from the bottom helps to remove the boiled off vapor and is therefore preferable. I am a big fan of big juice wells. . .this is my current complaint on the Ohm ega as well as the very high coil height relative to the air ports make for either long wicks or long legs.

Just some thoughts, I am an engineer also, although not ME. I’ve gone so far as to design a mechanical mod in Solidworks. I still plan on having it made, but its like 90% done and the rest of the work is drawings etc… .that I really dont want to do. It is all copper and designed to handle massive current with little voltage drop. . .it has a trigger instead of a button. Pricewise you just cant compete with the Chinese and they will stay cheap as long as R&D to them means “receive and duplicate.” (Just like America in our industrial revolution BTW.)

Very good points! I will take those into consideration. I have Solidworks, but am not real good with it. I do all my modeling in Mastercam. Although not quite as powerful, it gets the job done.

My plan is to model up a few tanks to get a feel for how they work. Then design a new one based off of input here. It’s mostly for fun, but I am a CNC Programmer so I have the means to make one.

And yeah, we could never compete with the Chinese. It’s really amazing how far they have come with producing a very cheap, yet quality product. The Crown is a perfect example. And the Aromamizer is a beautifully machined tank. Without having Swiss type machinery, it would be very hard to produce anything cheaply in small quantities.

Although, the shop I work at is right next door to a shop that has Swiss machines, and they are always looking for more work.

My company bought a Chinese mill. For $2500 it has 4 axis encoders with readouts (the table and the spindle are encoded), coolant pumps, lights, and it’s gear driven. Very easy to change speeds. I’m certain I am leaving stuff out. I would buy one for my house if I didn’t know what tools cost. Yeah, I have no idea how they do it and at least brand new it’s about like the lower-end Bridgeports for tolerances. The tables have wicked backlash, but it doesnt matter much when using encoders. Did I mention you could program it?

If you are interested sometime maybe we could have a chat about my mechanical mod too. I haven’t ran the design passed anyone that actually makes stuff (I am a HACK in the machine shop, and this needs lathe work.). I’ve designed it based on available stock, mostly from McMaster.