RTA…Refillable Tank Atomizer…A refill port accessible without the need to remove the entire tank assembly from your mod …Air flow control, again, without the need to remove the tank assembly from the mod…smooth action firm adjustability from open to close…operable during the hit, as well…Actually I am in the process of designing some tweaks on my LemoDrop…and these are the two biggest issues with that RTA…A shame, because it’s an easy build with great flavor…

After thinking a bit if you were to use the velocity style deck and get air from the bottom I guess if there was a way to block off the air hole and possibly the juice channels on one side that would accomplish the single and dual coil aspect. But probably an engineering and manufacturing nightmare unless there was a way to do 2 decks one single coil and one dual coil and make them easy to swap out.

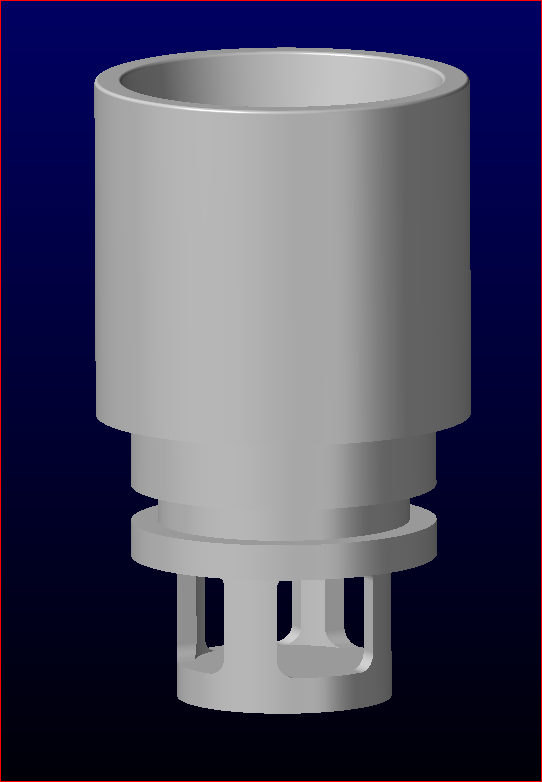

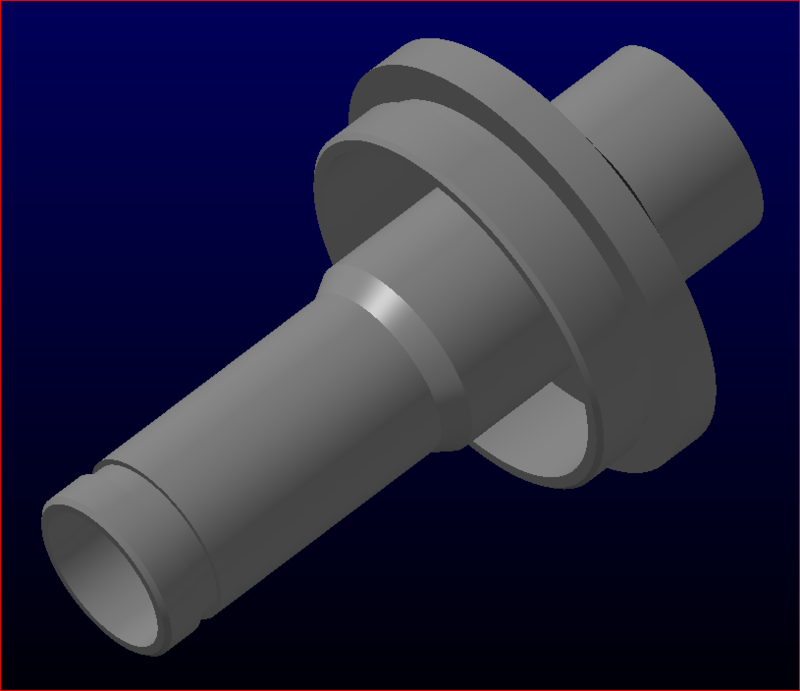

I have started reverse engineering the Aromamizer just to get a design to start working with. I have to wait to suck the rest of the juice out of it to get much farther LOL. I managed to finish the drip tip though…

I dont have an aramorizer so I cant compare, but I am not a hug fan of 510 drip tips, sorry. I like a big fat delrin chimney and I have not seen one of those that incorporates the spatter shield. . .would take a ton of real estate. I like a delrin chimney because I’ve nearly chipped a tooth several times on the bumpy roads where I live and also out of clumsiness. The big chimneys really seem to bring the flavor. . .I wish someone would just design a new huge cap for the TFV4 even. . .drive out the pin and add one that sticks with an o-ring and includes a seal to block off the juice port.

RE the velocity deck. I feel it sinks a rather large amount of heat from the coils. It is wonderful to build, but I think it makes the atty a bit of a pig on power. I like the Ohm ega design, but would prefer set screws and for the holes to sit closer to the air inlets.

I think creating air turbulence around the coil, preferably from the bottom helps to remove the boiled off vapor and is therefore preferable. I am a big fan of big juice wells. . .this is my current complaint on the Ohm ega as well as the very high coil height relative to the air ports make for either long wicks or long legs.

Just some thoughts, I am an engineer also, although not ME. I’ve gone so far as to design a mechanical mod in Solidworks. I still plan on having it made, but its like 90% done and the rest of the work is drawings etc… .that I really dont want to do. It is all copper and designed to handle massive current with little voltage drop. . .it has a trigger instead of a button. Pricewise you just cant compete with the Chinese and they will stay cheap as long as R&D to them means “receive and duplicate.” (Just like America in our industrial revolution BTW.)

Very good points! I will take those into consideration. I have Solidworks, but am not real good with it. I do all my modeling in Mastercam. Although not quite as powerful, it gets the job done.

My plan is to model up a few tanks to get a feel for how they work. Then design a new one based off of input here. It’s mostly for fun, but I am a CNC Programmer so I have the means to make one.

And yeah, we could never compete with the Chinese. It’s really amazing how far they have come with producing a very cheap, yet quality product. The Crown is a perfect example. And the Aromamizer is a beautifully machined tank. Without having Swiss type machinery, it would be very hard to produce anything cheaply in small quantities.

Although, the shop I work at is right next door to a shop that has Swiss machines, and they are always looking for more work.

My company bought a Chinese mill. For $2500 it has 4 axis encoders with readouts (the table and the spindle are encoded), coolant pumps, lights, and it’s gear driven. Very easy to change speeds. I’m certain I am leaving stuff out. I would buy one for my house if I didn’t know what tools cost. Yeah, I have no idea how they do it and at least brand new it’s about like the lower-end Bridgeports for tolerances. The tables have wicked backlash, but it doesnt matter much when using encoders. Did I mention you could program it?

If you are interested sometime maybe we could have a chat about my mechanical mod too. I haven’t ran the design passed anyone that actually makes stuff (I am a HACK in the machine shop, and this needs lathe work.). I’ve designed it based on available stock, mostly from McMaster.

That would be cool. If I knew anything about electronics I would probably want to tackle something like that next. But things just confuse me if it doesn’t have moving parts

Edit… most people see a part that looks like it needs to be made on a lathe. But just about anything can be made on a mill if you have the right tooling. A buddy of mine is a lathe guru and I had to prove to him this is true a few times before he believed me.

I bet in the right hands it could be done with a pocket knife

I spent some time trying to figure out a cool RDA to go with my mech. mod, and I think making a mech mod would be a lot easier than a tank. That said, I think the collective knowledge of the folks on this forum should be able to come up with a pretty rad tank. . .and it will probably be shipping from China before we can decide on the color scheme.

I am in though. I am not even a novice in SW, but if you ever need some of the advanced functionality we can exchange step files etc. . .

Oh. . .on the avatar it says my nick is already taken. I need to see if it is taken up by one of my websites or something. I know there was one other TRW years ago though.

I just upload my forum images here on the site. I use Gravatar for the calculator pages.

Sounds great man. When I get this going I would love to have your input and will share the STP files with you. We will have to send them back and forth so we each have the latest version.

Do you have a set of calipers handy?

This may be true after the draw, but during firing I have to disagree. And to me this may even be considered a desirable thing to aid in cooling…to a point.[quote=“therabidweasel, post:24, topic:37992”]

I am not a hug fan of 510 drip tips, sorry. I like a big fat delrin chimney and I have not seen one of those that incorporates the spatter shield

[/quote]

Check out the Steam Crave glass RDA. The top cap utilizes a (maybe rubber) wide dripper connection. The stock metal drip tip can be used but if you prefer you can use the supplied 510 adapter. I was sent one of these RDAs for review but I won’t be able to even start as the glass lasted me a day. Got a crack from who knows where. At any rate I will try to snap some photos and post them here. I’m using a 510 metal/acrylic on the adapter because I’m not a fan of metal drip tips at all.

Yes, several calipers, always…I blueprint motors.

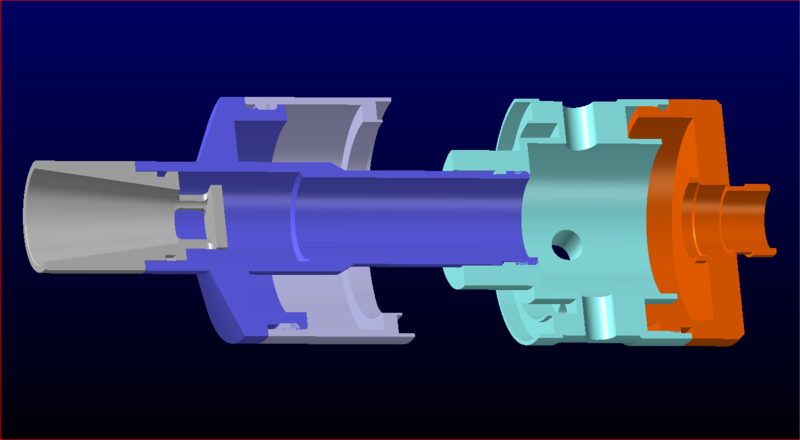

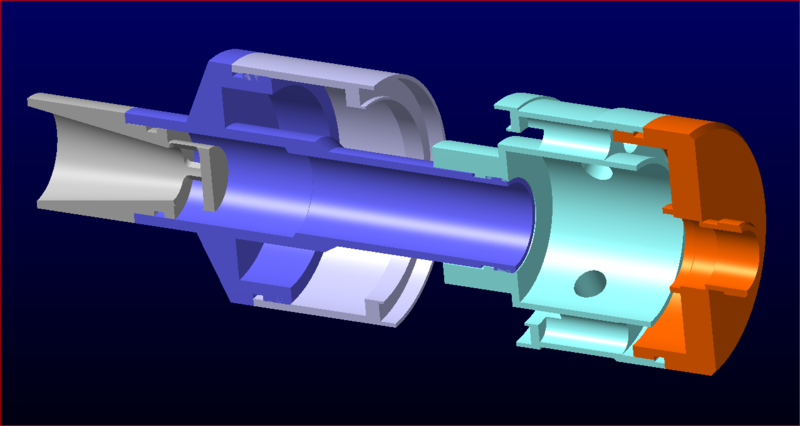

Here is a cutaway view of the Aromamizer minus the deck. I will have the deck modeled up and placed into this cutaway view later today.

I present to you - The Aromamizer! (within a few thousandths of an inch)

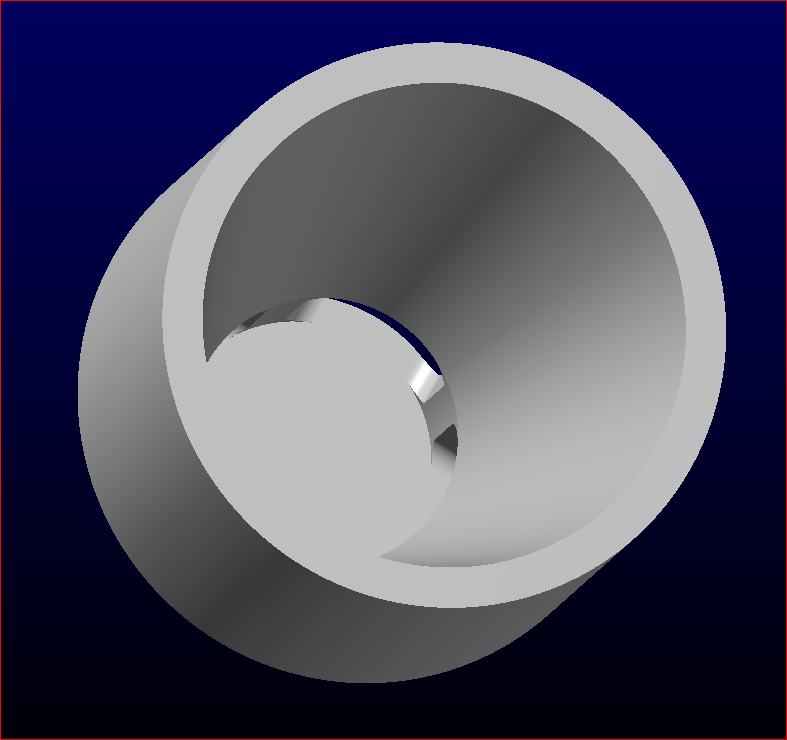

I also wanted to add a second cutaway view showing the juice channels inside the tank…

And then it is on to designing the ELR RTA!

And I have to say - Being a machinist and CNC Programmer/Engineer of 20+ years experience I can’t for the life of me figure out how the hell they make this thing for less than $50. It’s truly amazing, and a stunning piece of machined artwork. I couldn’t produce 1000 of these for less than $150 each.

Wow is that materials only or is labor calculated in there? I’ve wondered for years how they can do it. I recently bought a rotary tool similar to a dremel but smaller and one speed - 16,000 rpm. Came with a lot of bits too. $8 at harbor freight. If materials aren’t that high and its a lot of labor…

According to CNN’s online global wage calculator, which uses data from the International Labor Organization, the average annual salary of a worker in China’s private sector was 28,752 yuan (about $4,755) in 2012, or 38% of the global average.Jan 24, 2014

With most products made in China the craftsmanship is often lacking. But really with some of this stuff they don’t do bad at all. Well sometimes I feel like sending them some info on removing machine oil ![]()

That is exactly why not much stuff is made here in the US. Keep in mind the price of most of your high end authentic stuff such as the kayfun V4 or I think it’s called the hurricane tank (Swiss Made) They are both more than you said if memory serves me right.

Can we have a domed chamber?

Sure can. Kinda like the Ohmega. Did you ever get that?

Yep, I don’t like it much. The top fill is poorly designed. It pushed liquid out to the coils causing flooding  I suspect that it can be fixed by filing off a tiny part of the threading, like on the KayFun 4…

I suspect that it can be fixed by filing off a tiny part of the threading, like on the KayFun 4…

EDIT: Domed, or just a funnel-type dome should be fine

I’m not a maker by any strech of the word, but I admire stuff like this. and I gotta say, not to quote Darth Vader or anything but, “Impressive. Most impressive.”