Thanks a lot man. It’s obvious I can work for the Chinese. We will see how well my design skills are soon enough.

This plays a lot smaller percentage in machine time than most people think. The average hourly rate for most CNC machines in a machine shop in my area is around $100/hour. And some have people close to minimum wage pumping out parts. So the cost of the employee’s wages when figuring machine time is minimal, especially in production shops. The other factors are machine maintenance, electricity, cutting tools, Engineering, Process Development, etc. And of course profit is figured in there if the job is quoted correctly.

Usually a shop charges one rate for a first run, and a different rate for subsequent runs to account for the Engineering and Process Development costs. Machine setup time is usually included in there on the subsequent runs. Another factor is parts such as these would require specialized small tooling. Which can sometimes get pricey. And the smaller the tooling, the less tool life it has. So figuring a quote for something like this can be a real nail biter once production actually begins. Because you never know what you are going to run into.

Which is why the Chinese have become so good at copying things. They aren’t quoting anything. They copy a part. Then produce it. I would guess by the time they make their 2nd or 3rd part they have a price in mind aimed at making a decent profit.

The Chinese companies creating their own product line really have things figured out. Machine shops in the states make things for other people. To me this is just a silly way to do business on both sides of the coin. The machine shop should develop their own products to sell. And the customer should invest in their own machine shop. It would eliminate so much time for development of a product to have the guys making it right outside your office.

Sorry, back to the topic at hand…

Has anyone taken their Aromamizer atomizer apart? It appears the positive post is screwed into the plastic component which also seems to be threaded into the atomizer. But it’s very tight and I am afraid to turn it.

That is an amazing looking atty stand.

And now that i am going for more RTA, I am all about this if and when it happens!!!

Very interesting information. I can understand all that you are saying goes into the cost of producing the product. Please don’t apologize either because I for one really appreciate that explanation. I’ve had to offer similar explanations to my customers regarding the cost of moving freight because until everything that factors into a rate is explained, the average person has no idea.

I tried but it’s too tight. It won’t turn at all. So my guess it’s press fit or threaded with the diameter of the positive post larger than threading in the peek insulator. Either way I feel like I’m about to break the insulator when trying to use pliers to twist it so I haven’t truly forced it and it hasn’t budged either.

As promised, here is a look at the top of the Steam Crave Aromamizer RDA/Glass version. The black connector seems to be hard plastic, probably Delrin. Then there it is with the supplied drip tip, the adapter and the adapter with 510.

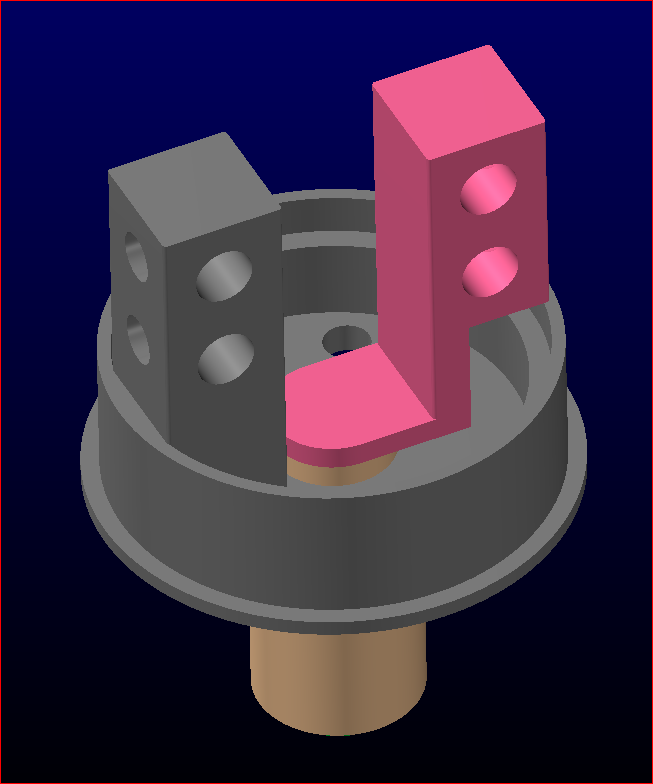

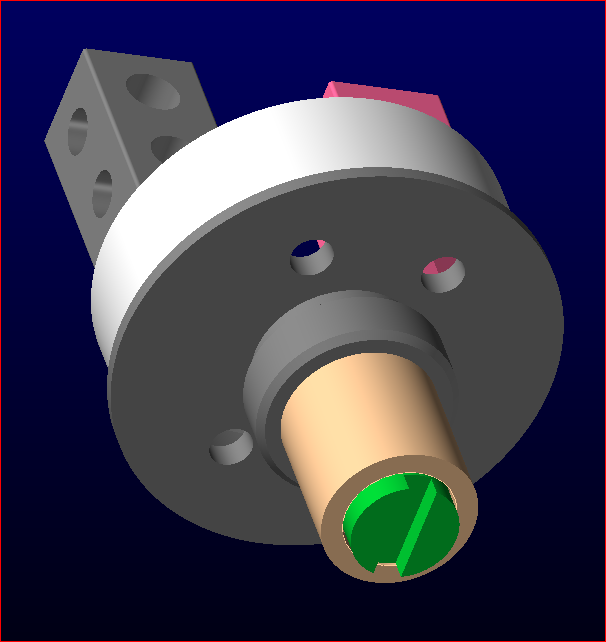

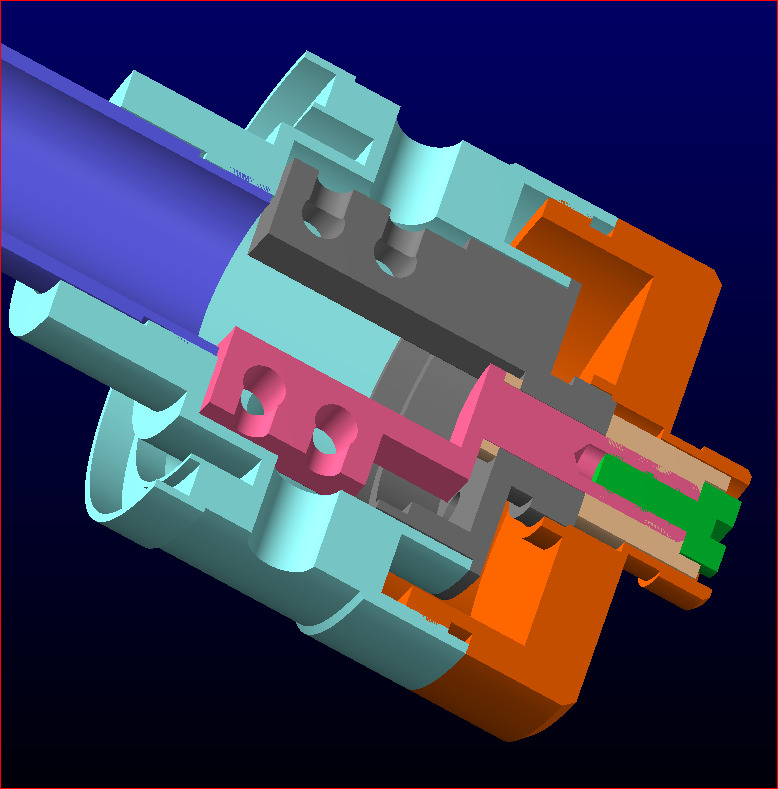

OK guys. The Aromamizer design is complete, right down to the pin screw. Here are some screen shots…

Wow …ten characters

That’s awesome

So, were you able to remove that positive post? If so was it press fit as it seems to be in the cross section or threaded?

very very impressed with your work and looking forward to this!!!

No, I couldn’t get mine apart either. I just designed what I assumed was there based on what would work. I am about 90% sure that what I designed is what it has to be based on what I could measure. Either way, that design would work.

After drawing this up I learned quite a bit. I really like the way the juice flows through this tank. The airflow can change though depending on how you insert the deck. I think the deck should have been timed with a tab so it always went in the same way. Maybe I’m over thinking it.

I will start on an actual tank design this week. It’s race season and work is going to be really busy. So keep the ideas coming if you have them and I will playing around with a few things over the next few days.

Thanks man.

One of the little annoyances I have with the Aromamizer is that to get the best vape and airflow, two of the air intake holes should be directly aligned with the coils. This is possible at no more than a quarter turn counterclockwise once screwing the tank down since there are 4 air holes. I would prefer the air intake either being movable or the deck be adjustable so that when the tank is screwed down all the way it’s aligned. Of course with the expansion/contraction of metal in various environments, a static setup most likely makes this impossible, but it would be great if I didn’t have to adjust this every time I screw the tank down or bump it between vapes.

A timing notch cut into the deck and a tab on the housing would solve this. Kinda like the Kanger Sub-Tank Mini V2 I think it was.

The positive post shouldn’t touch the negative post/frame - Shouldn’t there be a spacer or something? ;D

Lol, oh yeah. I forgot to change that. The peek was supposed to go all the way through. Good eye!

Sitting at work on break… I am wishing I had brought my CAD file with me!

I have been repeatedly saying Single coil or Dual coil option but please have a look at the method I used for building my Velocity Dripper in this thread

interesting-velocity-build

I think this means single coil dual coil problem solved but I have no idea if this would work other than by looking at your modeling pictures because I do not have one of the tanks you are using for this.

At some point this week I’ll give your single coil Velocity build a try in my Aromamizer. I have a feeling leaving the AFC band off will not make it too airy as the build will inherently restrict airflow anyway. May be quite interesting the results…in a good way.