I recently got a griffin tank coiled and wicked it and it leaks like a sieve. I didn’t even take 3 hits before I had juice all over my fingers. Ok…not enough wick. So I cleaned it up and put more wick in…down to the bottom of the juice channels. My thinking was go to the opposite extreme and once we know the bounds we can dial it in from there. It still leaks. It emptied a tank just sitting on the bench in about 3 hours. Its like I’m missing an o-ring or something. This shouldn’t leak this fast. I’m going to look up more UT videos but so far this seriously sucks! Any ideas? You want pictures?

My Griffin leaked one time. I think it was because I filled the tank before closing off the juice control and the air control.

When wicking I have the wick just even with the bottom of the wick ring, the wick is tucked inside that ring (I have heard some people don’t use the ring but since my tank is still new I am still using it, and for me it’s a good guide). Besides that one leak I had with it that one time, I’ve filled the tank (closing off the juice control and air flow control each time) probably 15 times or so, no issues.

Hi, I agree with Tut, I’ll run through the way I use my Griffins and Crius for that matter just to be clear. Use a coil with at least 2.5mm ID to ensure you have enough wicking material but make sure it is quite loose fitting inside the coil, the swelling will tighten things up once you fill up.

Have the wick end just showing 1mm or 2mm underneath the ring and loosely spread over the whole channel.

After replacing the glass close off the juice flow hole, fill the tank and as you open the juice flow quickly take a couple of dry tokes to equalise the air pressure.

Let it sit for 3 or 4 minutes to fully soak into the wick, have another dry toke now and then to help things along and you should be good to go with no leaks or dry hits. Each time you fill don’t forget to close up, fill up and again as you open the juice flow up have a quick dry toke to balance things.

I do close off the juice control & the airflow for good measure. And after filling it I don’t notice any leaking for a little bit. I put it on the mod and take a few hits and its like the flood gates opened up. I did see that the o ring on the deck is a bit chingered, so I replaced that one.

Tried this a 3rd time. The wicks were just barely below the ring. I closed off the juice control and the airflow…again and filled it up. Everything is good so far. No noticable leaks. Put it on a mod a fired it a couple of times paying close attention to any and all air bubbles. I then noticed that the juice level decreased to just above the juice holes whereas before I put it on the mod the level was constant at the top of the air chamber…and now its leaking again. Guess I’ll contact VapeNW to see if I can send this one back,

That is a shame, I thought you had cracked it for the first two lines, it is really frustrating to go through a bunch of re-wickings to discover that wasn’t your problem after all.

I hope you can get it exchanged, it sounds like you have a legitimate reason and the seller shouldn’t be able to say it is user error.

@Redbud, how far open do you keep your juice control? What pg/vg is your juice? I was thinking of giving this one more try with 100vg and leaving the juice control closed for a while to make sure that it isn’t leaking somewhere else. I have since replaced ALL the orings except the 2 small ones on the upper air chamber.

Hi, I have it fully open, M. I use 60%PG/40VG so it is pretty runny. Max VG must be worth a try along with your o-ring replacements. Good luck.

Edit, I assume the top o-rings are ok as you haven’t replaced them? From all the top fillers I use this is a great way to cause leaks.

I have a tfv4 mini that leaked like a sieve because the top seal (or ‘gasket’ as Smok call it) was not 100% and needed shaving to fix it. I believe Smok have now sorted these top fill seals now. I digress, the point is if the top isn’t fully sealed it doesn’t matter how well it’s wicked or the juice type etc, it will always leak.

I did replace the large oring just under the top cap. I figured the same as you did…if that oring doesn’t seal properly the juice will just run out. I did a test where I put the top part of this together, i.e., the glass, upper and bottom chimney, and top cap. I then used my finger to plug the hole where the drip tip fits and blew into the bottom of the glass. No air leaks. That was after I replaced the glass orings and the top cap oring, so that part looks to be good. Well, sort of…it doesn’t determine if the juice would leak into the chimney. I did not replace the oring that fits around to top of the top chimney, nor the oring on the bottom of the top part of the chimney. Those are the only 2 I haven’t replaced.

I’m thinking now that it may be one of those 2 orings that are causing the problem. I “think” that it didn’t start leaking until I tipped the whole thing on its side to adjust the airflow. Which raises another question…does adjusting the airflow always cause the juice control to move? It does on mine and that’s really annoying.

I have 2 of these tanks. One of them has more resistance when turning the juice control. Catch myself looking at juice control all the time while using it. Sometimes it moves if you pick up mod by the tank.

My juice control does not turn when adjusting the air control ring, I do make sure I am only turning the air control ring though.

If I turn the tank by only holding the glass and turn it either left or right, I adjust the juice holes, the air control does not turn (open or shut) when I am doing this. Having said that… if I do adjust my air control via turning the ring for the air control, it turns smoothly and without effort.

Agreed. Beat me to it. ![]()

I’ve only had 1 leak before and that was right after wicking a new coil. My problem was that the wick was touching the airflow hole, that caused some leakage, just a thought but maybe try keep your distance from that hole. Otherwise it could be an o ring missing. Good luck figuring it out.

At this point I think I’m done with this. The last test I filled it (with the juice control and the airflow closed) and opened the airflow just a bit. i left the juice control closed and let it sit on a atty stand. In 4 hours it has leaked out about half of the tank. If this thing leaks with the juice control closed off then there isn’t much I’m going to do to stop that leak. I believe that somewhere I’m missing an oring or an oring is bad and I haven’t found it. I think I’ve replaced all but 2 but I’m done at this point.

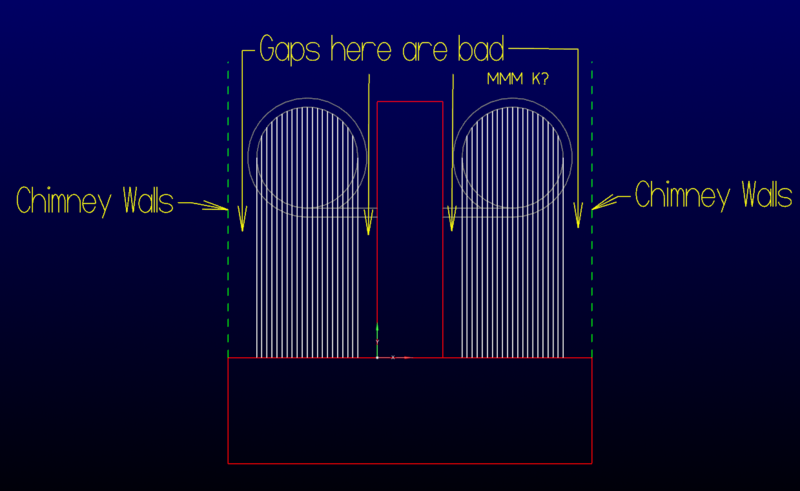

No leaks here. But I will say that I have learned a little trick whenever this happens with a tank. Your wick should come down and into the juice channels. But the area between the coils and the top of the deck is real important too. The wick in this area needs to remain fluffy and it should form a wall between the posts and the chimney when you screw it on. This will block off juice flowing into the air channels. Now that I have started paying close attention to this I have not had a single leak.

I’ve had leaks with mine twice. Both times I cured it by pulling the deck out and repacking the wicking in the channels so they completely close it off while still being even with the bottom of the ring. You can do this without losing your juice.

no Griffons here…sorry, no valuable input on those. I can say that the Aspire Triton v1 leaks really bad no matter what coils or how viscous your liquid is. It is such a beautiful looking tank too…and feels like a tank. I still see them on sale in places occasionally…to be avoided for sure. I called the retailer and eventually Aspire and got no love at all there. They did come out with the Triton 2 pretty shortly thereafter, so I guess that was their way of admitting the engineering flaw. Wasn’t a cheap tank either, especially a year and a half or so ago.

On the sides of the posts, i.e., where the wire goes into the holes? Not the side with the grub screws?

However I think I may have got this resolved. At first when this happened I thought I needed more wick so I ran the wicks longer into the juice channels. That didn’t work. This morning I had an epiphany. I do need more wicks but they need to be wider, not longer. I was cutting the wicks (organic cotton) at 3/8" width. This last set I cut at 5/8". As I was screwing on that useless ring, I thought, boy that is alot of cotton. Turns out I was right…it is alot, but after an hour sitting on a atty stand…no leaks! So far so good. I’m gonna let this sit for a couple more hours and see how this works.

Edit: at this point the wicks fit pretty tight in the coils but it seems to vape ok. The coils are 2.5mm. I think I’ll try 1/4" and also a 3mm coil.