BACKGROUND:

When I first went down the path of using this equipment for e juice purposes I was totally in the dark about how it worked and what was available. I read a lot of guides to e juice making and found repeated statements consisting of essentially “do this” “unless you have a homogenizer.” Upon a little investigation I found that the equipment is generally far beyond what most if not all DIY mixers would or could pay to own. I wasted time attempting to get the “high shear” effect with an overhead stirrer. Fail.

I then bought a used model made in Asia that retails new for about $800. It had a very small 5 mm probe/generator. It worked…for about a week. That was long enough to develop an understanding of the process. I then purchased what is purported to be an american made unit new for a ‘good’ price . Retail was approximately 3K. I didn’t pay anywhere near that. It has a large motor but due to price I bought a 7 mm and 10 mm generator. Maximum volume of the 10 mm is about 120 ml of e juice. I still was unsatisfied and wanted to mix larger volumes. This led to making my own rather than pay what I felt was an exorbitant price for a larger generator.

DESIGNING THE GAME CHANGER

So I started with a 5 mm and then purchased a 7 and 10 mm generator. I then began researching other makes and models and then started purchasing, using, repairing, and selling surplus units from universities and other sources. From this gained knowledge I then starting designing mine with unique features optimized for liquid/liquid e juice mixing. To be very clear I did not copy any makers design. While I’m not willing to give away the farm, there are multiple mechanical functions being applied by the workhead or rotor/stator mix chamber configuration. I altered them to suit.

The first design consideration is always safety. All materials chosen are FDA/USDA food contact approved and both corrosion and chemical resistant. Mechanical safety is assured.

The second consideration was whether I could design and produce an affordable device for the DIY communities that has full functionality and high quality. I believe I have though the drawback is the wait time. Outsourcing would likely quadruple the costs.

So in a no compromise mindset I chose materials that are more easily machined than the all stainless steel common to the market. I also settled upon 2 sizes. However, industry standards for lab sized homogenizers start at 5 mm then 7,10, 12, 20 and 30 mm outside diameters.

The small size GC is 3/8 or .375 inches outside diameter. 10 mm is .393 inches so very close. The large size is 1/2 or .500 inches, slightly larger than the typical 12 mm units on the market.

WHICH SIZE?

The question of mixing small 10 ml volumes with the GC has come up repeatedly. It can and is being done but my opinion is that the 10 ml tester is a product of the conventional method . Increasing it to 15 or 20 for use with the small GC is recommended. The “small” unit is actually a mid sized lab unit. I chose a range of function suited for mixing up to 120 ml. However, 15 on the low up to 100 is probably its best range. My design target for the large was 240. Users have reported 500 ml by moving the generator around.

I did not feel like making a small generator due to their small range of capability. 5 mm would likely top out at 10 or 15 mls. 7 at about 30. I didn’t feel like mixers would want to spend a couple of hundred dollars on a low range of volume device. I can though if there is enough interest.

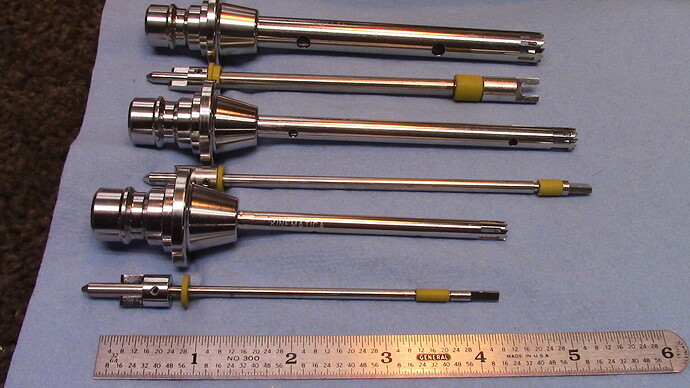

Pictured below is a model made by Polytron / Kinnematica that includes 5, 7, and 12 mm generators. I consider Kinnematica the “Rolls Royce” of this industry. I have some available including what is pictured. They are used but in like new condition.