Bought this last week and nothing but leakage out of the air vent

Using with my own coil build .Everything is screwed in correctly so why am i getting this problem?

I had leaking because I screwed the RBA head in too tight, thus deforming the small o-ring. Once I realized what was going on, I screwed it in lightly, ensuring the o-ring did not distort, and no problems since

Have you tried closing the airflow before filling it?

Yes. And it doesnt fully close anyway. There is still a gap in on each one

When i opened it up i will be honest the head was loose. No idea why. I screwed it back up and not overtightly and yet im still having the problem. I have now put the triple coil in what came with the tank and no problem…part from having to bang the wattage up to get a decent vape and draining the crap out of the battery.

I prefer my own coils and this is bugging the crap out of me

Two possible problems…One not enough wicking. Two, though it appears seated correctly the coil may not be screwing in completely. Being you do not have a problem with the stock coil that says the threads on the tank are fine. I can not look at my RBA because it is installed and juiced up but if the oring is like the stock coils it does not seem easily removed. If you can remove it easily then take a fine wire brush to the threads of the RBA. If not just screw the RBA in and out a few times and hopefully any burrs will be taken care of. As @daath said, do not over tighten. It’s important to keep that Oring in good shape and not distorted. Also be sure the chimney is completely screw in as well… One of these things should be you problem, good luck…

Could just chalk it up as a faulty unit, ditch it and get the dual coil rba and save yourself some frustrations…

I’m sure it’s not what you wanna hear, but I hate to see a brother frustrated

According to a vid tutorial the wick only just goes over past the base so the two slots at the bottom show no wick.

Is this incorrect?

You have to put enough wicking so as to “clog” the slots for the purposes of filling. . .it will still wick just fine, you just dont want juice making its way past the wick and into the airhole chamber. I left maybe 1/8" sticking out. . .hemp wick, a little dicey compared to cotton because it isnt so squishy, just make sure you clog the slots so juice cant just run in there.

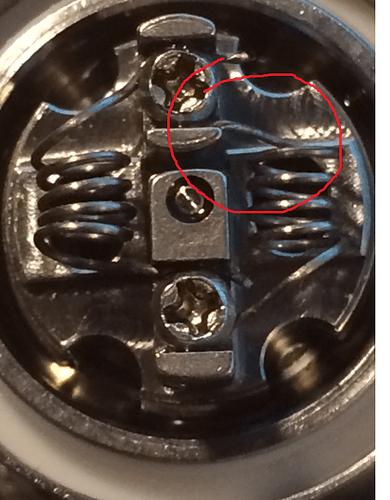

thats a bad pic

True but should be enough to get the wicking into the juice channels at least. Otherwise flooding can occur…I bend my cotton upward and install the cap. Then I wet down the cotton and take a very small screwdriver and arrange the cotton into the juice channels. Works for me. Come to think of it, if you are not getting the cap completely down I imagine you could get some leaking. That is why I bend the cotton upward so I do not get cotton in the threads when screwing on the cap…

hemp wick…where does one acquire such item?

I’ve struggled with this myself. The single rba is the easier one to deal with because there are only two juice channels. I’m going to share what I learned about both these to help whoever may read this thread. But I do recommend the dual rba for this tank as recommended by Pro_Vapes and Daath

First the single RBA. Make sure you’re only building your coils about half the width of the RBA itself, maybe a tad wider. Otherwise you don’t leave enough room between the outside of the coil and the inner wall of the chimney without pressing on the wicking. The chimney should be able to slide down without moving the wicking. However, IMO this applies when you’re not using this method -

I use this quite a bit but still get some leaking on occasion. When that happens I simply pull the build and arrange the wick with a precision screwdriver (chimney off) so that the wick is sitting flat on the RBA deck and covering the wick channels with just a tiny tad of wick in the channel. Works every time.

For the dual RBA, the first thing to watch is your coil build. The proper way to install coils is shown below. As you know in a build like this, the coil has a leg that comes off the top of the coil and one from the bottom. The bottom one (circled below) is essential to put on the inside of the screw as shown rather than the outside of the screw. If on the outside the leg will be in the way of your wicking. The wicking method, though, is the same as the single. Just be sure your wick is not going over the air holes under the coil.

Hemp wick:

I picked it up on amazon, it’s a brand called “green remedy.” A fat sack of 9+grams for $10. It goes a long way, even building dual coil drippers.

Mine hangs all the way out of the rba with the cover on, just a touch…not to brag. I’ll try to shorten it up, maybe rewick with cotton and see if I can hit this coil any harder. Maybe the wick is blocking the passage too much, but I’m way underwhelmed.

One of my favorite dripping juices is nasty as hell on the 3 coil, where the John Wayne clone is AMAZING.

OP, any progress?

One day of use and with the rba on my tfv4 and dropped it. Nothing abnormal for me drop my mods and tanks all the time( sig 150 in 2 feet of water) so far all still work. This time my mod is saying check atomizer with rba installed. When I put factory coil in though, no problem. Can’t find anything wrong with the rda though??? Rda was inside the tank so I can’t figure how it could have been damaged. Any one can help???

Perhaps the impact damaged an insulator. I would tear it all down and inspect and if you don;'t see anything wrong, rebuild and try again. What mod are you using? If it has 18650 batteries (especially the xCube!) pull them to “reset” the mod. I have to do that about ever 3-4 battery changes. Also inspect the batteries to see if impact damaged the pos or neg ends.

I have torn down and cleaned the tfv4, or are you saying tear down the rda? How?

Just curious, did you rebuild the RBA? I had trouble with the wire being cut by the screws. Though it appeared as though the wire was in place and screws tight, it was actually cut and just inside the hole hanging. Possibly jarring the tank finished the cut. Just a thought. Make sure the center pin in the base is all the way in too, it must contact the coil of course…