My friends the 510 on the Gen has really p!ssed me off. It finally took a dump and I had to fix it. Apparently I am not the only one that had this issue. There are a lot of people that this has happened to.

I cuss a lot in this one so you will have to forgive me. Also, I am not the best a soldering so that should be good for a laugh.

By the way, how do you like my thumb nail? Took me forever to make it and it makes me laugh because I always wanted to be an artist but I got a D in Art. Basically, I suck. LOL

You crack me up mate.

Soldering issues or not, you got it done!

Well done on that!!

Part of the reason you’re having problems soldering, is because you are using an iron, instead of a pencil. Most irons typically start at 75w and go up from there. So trying to get enough heat transferred to the areas you want it before burning the plastic insulators, or surrounding mod body (since most are plastic anymore) is a difficult task in and of itself using an iron. You either struggle with trying to hit the trigger for a brief moment or two hoping to get enough heat before it’s too much (which is what it looked like to me), or you go right past into the “aww shit, I just melted the…/insert random part here/” zone.

If you get a soldering pen/pencil (depending on where you shop), and some still call them irons (though, the distinction came about decades ago for just this reason: to identify the power difference), you’ll probably see your ‘skills’ develop far more quickly.

There’s still some techniques to learn, but they’re far easier to learn when you’re not fighting two (or three) battles at once (right amount of heat to make the connection, getting the wire angle, trying make sure you don’t melt the insulators or mod itself!).

The other thing that might help you, is a set of “Helping Hands”. They also have fancier versions with a light if you prefer…

I know most don’t have the choice, but one of the first things I look at in a mod is the 510. It’s really only one of the few things that can give any kind of layman’s indication of the quality of the unit. (While this is not always the case, my thinking is, if they’ll skip on one of the more important points of power transfer, then they’re probably skimping on internals.)

I’ll rarely consider buying a mod if it’s got compression fit 510. (Like, almost never.)

Compression fits are usually pretty easy to ID.

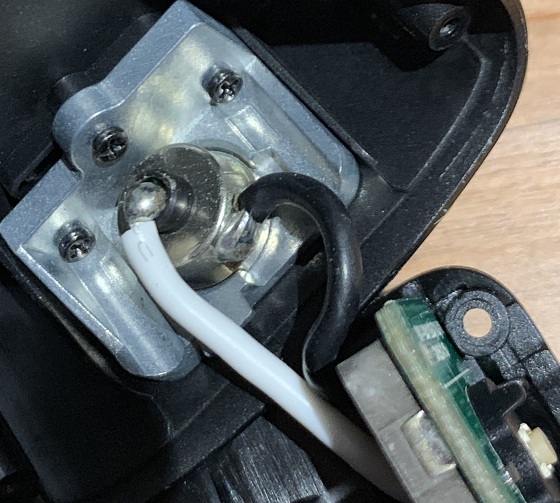

They’ve usually got a solid round top (like the Alien):

Which, as you can see in the above shot, it only really had about an 1/8" (maybe 2mm) of a ‘bite’ on the 510. (Not much to hold onto, considering the amount of force some use to screw on an atty…)

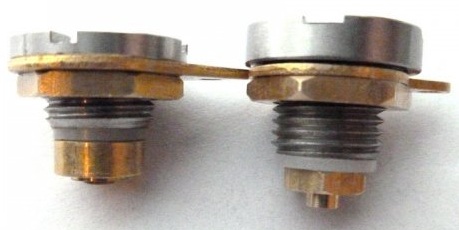

You can see the fitting better in the next pic:

While it appears to have gotten a much better ‘bite’ here, the problem is still the fact that it’s not durable over the long haul. (Almost planned obsolescence eh? Hey! When it gives way, most users will have to buy another mod!)

The Gen (as you found) uses the same type of 510.

Compression fit.

Even though they “dress it up” with some temporary reinforcement against lateral movements (which, hey! Something’s better than nothing, so credit there for whatever it’s worth), it still does nothing to prevent the stress of the twisting motion that’s applied through the compression-fitting of the 510 by installing/removing the atty.

Joyetech, Kanger, as well as Wismec have shipped a lot of units with compression fit 510s as well. Even seen them in the old IPV stuff (while a bit ‘fancier’ -as they had serrated ‘teeth’ incorporated into the compression clamp portion, they still share similar problems over the long haul.)

I find that more often than not, slotted 510’s are typically (not always) the type that uses a nut to cinch the 510 down.

Whether it’s the small ones…

or larger ones…

These are a far cry better than a compression fit IMO.

The only thing is, you would be better off tinning the part that you intend to solder a wire onto, before the 510 is installed/assembled!!

If you don’t, even with a 25-30w soldering pencil, it’s possible to apply heat too long, or encounter an ultra-cheap/flimsy plastic insulator, and end up with the following:

Enjoyed the video, and I’m sure it’ll help some out!

Hope some of my ‘mile of tips’ helps you for any future attempts! =)

Rob

After the soldering at 9:40: Now, let’s test to see if this is working

forgets to put an atty on the new 510

Thanks for the laughs

Thanks for that dude, means a lot coming from the Mod Father.

Thanks for the advice bro. much appreciated.Believe it or not, I do have a pencil but it doesn’t work very well. Oh, and I HAVE indeed melted the shit out of a mod, the plastic inside the 510 and the wire. Ya, I would love to practice but I’m not sure how. Tinning? Didn’t I do that at 8:21? is that not tinning? I have watched some video’s but have yet to find one that I can learn on.

I bought this once upon a time but it’s to buisy. I should have gotten a smaller one with less arms. LOL

HAHAHA, I did but I couldn’t edit it so that it made sense and then I accidentally erased it and I just wasn’t going back for it.

I definatly could have done a better job so I just went for the laughs more than anything else.

![]()

![]()

![]()

Oh ya, what kind of roast do you like and is it true that a dark roast ruins the flavor or that inferior beans are used for dark roast?

Well I was wondering. 9.99ohm is either no atty or very bad soldering

It depends on the bean (or blend of beans) that are used as well, what kind of coffee I’m making (filter/espresso/cappuccino/french press/…), what the occasion is or what it’s paired with… Like with my juices, food and many other things, I like variation and I rarely drink the same coffee all day long.

Usually I don’t drink very light roasts because they have too much of acidity and French, Italian or Spanish roasts (very dark, nearly black) are usually not my thing either. BUT, a lot of it depends on the bean. There are some beans that really shine in a light roast and some that are good even if you nearly burn them.

The taste and complexity of the coffee’s flavor depends on the type of bean, how and where it’s grown, the soil, how it’s processed to get the green beans out of the berry. For Arabica coffee, the higher the altitude the coffee is grown at, the more complex the flavor will be.

I’m dumbing the process down a bit now but that’s just to understand the basic process of roasting. When you heat up your roaster and dump the green beans, you’re entering in the drying fase. There’s not a whole lot of flavor development going on during this fase and it you smell them, it’ll be very grassy, not at all recognizable as coffee. The beans will turn from green to yellow and then cinnamon color in this process.

The water content from the bean starts to heat up and the steam will suddenly crack your beans. You can hear it and it sounds like popping popcorn. Now you get into the development of the coffee flavor. All the well known aromas begin to develop at this stage. Initially your coffee will have a high acidity with a lot of fruity or floral notes (depending on the bean and its origin) and while you keep roasting, a lot of chemical processes (like the maillard process we know from steeping our juices) start to alter the flavor from acidic to bitter. You’ll go more to chocolatty/nutty/woody notes but you’re also losing sweetness and acidity in the process. The very darkest roasts completely destroy any complexity in the flavor and leave you with a mess of carbon… whether you use a very cheap or a very expensive bean, carbon is still carbon and it’s all going to taste the same.

If you have beans that have fermented for too long or something went wrong when it was processed, being transported or stored, the safest way is a dark roast because all off flavors will be burnt to a crisp. Coffee can get moldy, a lot can go wrong in the process of getting the beans out of the fruit and they are stored in jute bags for transport and storage so if they’re kept too long in them, it can start to taste like jute. If the beans sat next to exhaust fumes during transport, you taste it, … lots of things can put off notes in coffee and a really dark roast takes care of all of that ![]()

If you want a high quality coffee, a specialty coffee, you’re going to want a light roast, at most a full city roast to keep all the complex flavors in the coffee.

Unlike popcorn, you’re getting a second crack if you keep roasting. That’s when the oils are escaping your beans and you want to keep those in the beans for your flavor. If you buy coffee and you see that your beans are oily, it means they’ve either been roasted too long or they’re old. Either way, you don’t want to spend a lot of money on it.

Fuq, dude… you know your coffee bean shit!  I’d say… start your own business… but, then again, why ruin what you love to do by having to deal with arse-hole customers!

I’d say… start your own business… but, then again, why ruin what you love to do by having to deal with arse-hole customers!

I know that you are familiar with the concept (sorry if I left the impression otherwise). ![]()

I was just trying to say that it’s going to be very hard to do with an iron.

I’ll see if I can find a good one for you. ![]()

Again, I think you did a great job with what you were working with. ![]()

Not easy!

Here’s my buddy Dan … and he builds mods.

Outstanding @big_vape.

@Dan_the_Man I always use flux, so always put some flux in your flux capacitor !!!

@big_vape Thanks for the vid. I’ll watch some more of his work.

@SessionDrummer Thanks for the vid bro.

I think I know what it is

Thanks, man… ![]()

Actually it is 66.6 my favorite number

![]()

![]()

![]()

Bow down before me mwhahahaha. or something like that. You might know this already and you might not but 666 is not satans number. it is the number of man and the beast. Guess which one I am.

Hi Rob,

You got me thinking about my mods (Sigelei 30W Mini, eLeaf Pico 25, and Vaporesso Swag II) - and with the “ENDS of Days” soon approaching on May 12, 2020 - how long they may hold up in usage, and whether I should stock up a bit more, in order to avoid the demonstrated grief surrounding re-soldering.

I remove and re-attach my tanks daily, in order to wash my wicks of NET-glop in hot water. You are referring to the twisting motions that take place when (close) contact is being made ? I place a tiny amount of Glycerin on the atomizer threads whenever re-inserting gently (in order to smooth the thread frictions in travel). Small amounts of that Glycerin also tends to inevitably end up lightly coating the bottom of the atomizer connections. Such amounts do not present an electrical resistance problem.

I was wondering if that (Glycerin) lubrication (might, possibly) tend to reduce the “lateral movement” forces that you describe (which I assume occurs at times when atomizer is torqued-down, when either attaching/dis-attaching electrical connection) ? That seems like the time such those forces matter. My thinking is that this lubrication, combined with gentle mechanical torque actions, might possibly help ?

No.

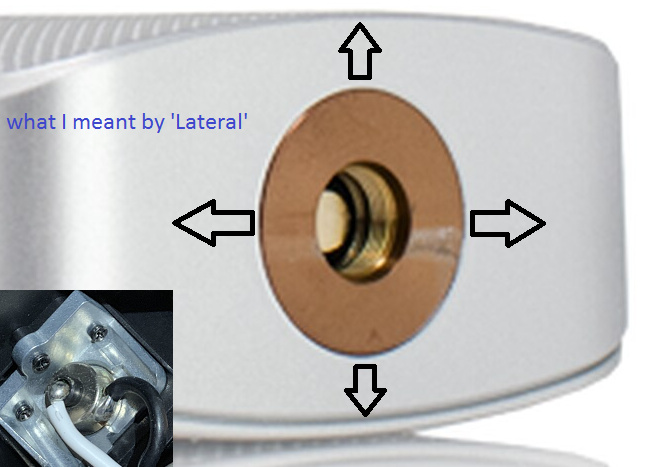

But, I should probably clear up what I meant by lateral…(when I said “Even though they “dress it up” with some temporary reinforcement against lateral movements”):

I was trying to say that their little pot-metal block that they used to ‘stabilize’ the 510, is only working to stabilize the following movement of the 510:

(note the black arrows)

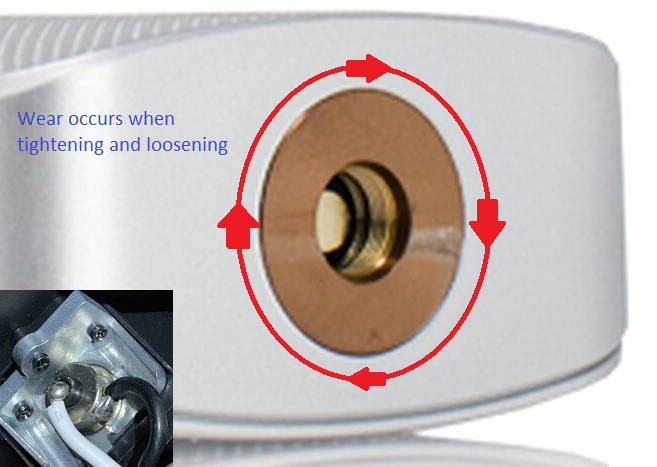

I was also trying to say that the pot-metal brace (inset pic, lower left) does nothing to negate/offset the applied rotational forces (rotation of the 510 seat) which are sometimes applied by those who ‘don’t know their own strength.’ ![]()

Meaning, the atty has, in reality, already reached the maximum torque necessary to secure it in place, but that the user went above and beyond that (hence the “it still does nothing to prevent the stress of the twisting motion that’s applied through the compression-fitting”), and then has to overapply force again in reverse, to get it off. This is the cause of most premature failure on compression fit 510s.

As for:

This probably helps to some extent (assuming it’s not over-tightened), as well as reducing friction I’m sure. But honestly, I can’t imagine threads being that rough to warrant it.

I think my biggest concern would be the following:

While I don’t have any concern about “Such amounts do not present an electrical resistance problem”, my real concern is more about the accumulation of liquid building up, and then running down into random parts of the mod…

The biggest preventative measure IMO is what you already noted:

![]()

![]()

Thank you for your in-depth reply !

I started out with an (already) used Sigelei 30W Mini that a mutual friend kindly gifted to me - and it seems that its thread - as well as that of a drip-atomizer or two were tending to “catch” when threading-in (to the extreme at this point on that particular unit). I think that one thread (or another) involved were possibly damaged, damaging threading mated-to. So, following that, I started very lightly “lubing” the threads of the atomizers with a tad of Glycerin, in the hopes of avoiding such phenomena in the future.

I hear you there. That does not seem to happen in the case of my Sigelei mods (a couple of which I have endeavored to open-up and inspect) - but it could happen on my eLeaf and Vaporesso - and I don’t really want to be opening those up (if I can help it) - as I am (although with electronic knowledge) rather a “mechanical klutz”. Glycerin is a mild non-conducting (“glycol”) alcohol - but it might perhaps impede heat dissipation, and/or (possibly) glom-onto any dirt/crud (or perhaps even react with such).

Indeed, if one could get the larger (ground-connected) part warm enough to “tin” well with solder, then one could apply a “glop” of solder to the (pre-tinned) electrical wire (to be attached) side, and mate that solder “glop” to the tinned larger (ground-connected) part fairly quickly - but the catch seems to be that it may well be that all soldering (including pre-tinning) can take place (only after) inserting the part into the casing (which unless being of metal construction, is in danger of melting from overheating). Musty stuff !

We need an emoji with a smart ass smirk ![]()

@Raven-Knightly Nice to see you responding on a thread.

@Sprkslfly what program are you using to modify your photos?