I would very much advice looking to @anon36682625 for knowledge of this process. The man knows what he is talking about.

Does that mean I can come out of the bunker now?

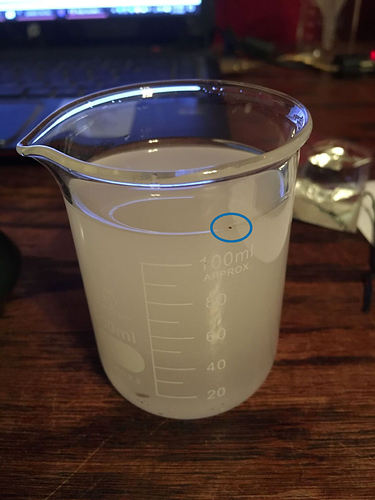

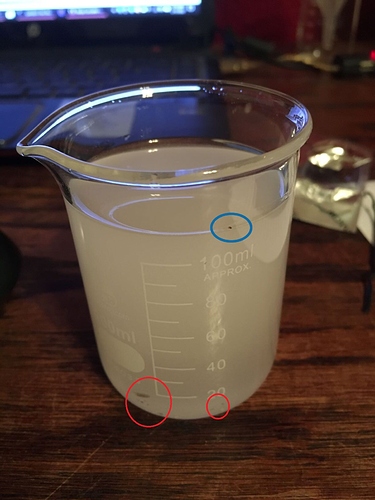

100 ml Snozzberry test

had to kind of step the prob down like i did the large batch to get the cold vg to mix … but even doing that mixing time was cut by 90% in the future the homogenizer will be my go to device for mixing small and large batches . think yes i will preheat the vg in the future before homogenizing. as articles have pointed out vg does not homgenize unti 60 degress celsius , so i expect some better results next time .

edit : is worth $200 in my opinion yes it does what its supposed to do …

yes i about threw the whole mix away when i saw that in the pic till i realized it was something on the outside of the glass.

the red you circled is the desk showing thru bottom of glass .

I don’t use an homogenizer but I do use a hand blender like this one :-

I tend to make shake-n-vapes (lots of fruit) so speeding it along using one of these makes things so much easier. I’ve also got down to .1mg (yes point 1) of nicotine which is only about 2ml@75mg in 700ml of liquid… and at that point while its probably more psychological than actual nicotine dependency liquidising it is probably the best way to make sure its spread evenly throughout the juice. It also makes sure my flavours are also well mixed. I tend to fritz it until it goes cloudy throughout the liquid (about 60 seconds, which increases the volume by about 5ish% due to aeration) and then wait for the bubbles to rise until clear (with clingfilm over the top) and then bottle.

After just watching the vid that @anon36682625 linked, its interesting to note that while my method is prone to aeration (even if the head is always kept below the liquid surface) a homogenator theoretically doesn’t add any air so is less prone to oxidation. Although I wonder if long steeping, or other methods, are basically introducing that via a longer term process, especially if people periodically shake the mix or as someone once mentioned after bottling it using a paint shaker or some other mechanical means.

Well, assuming you keep the lid on, you wouldn’t be introducing any ‘new’ oxidation that isn’t either already in the bottle or may wiggle its’ way in through the lid or bottle regardless of whether it’s disturbed (shaken occasionally) or not. Oxidation doesn’t help the maturation process; it is actually the enemy of our juices and especially our nic. It is the homogenization of the mix that determines its’ maturity. And that’s achieved naturally over time or instantly via high shear mixing.

I don’t have a high shear contraption, so much of the time I simply mix, shake, and hide. But when I need some juice sooner, I use a Sous Vide to heat it to 60C, shake it aggressively by hand, and set it in the USC for a bit (adding the nic only when I am finished with that and the juice has cooled to room temp). For ‘shake and vape’ types that are typically ready in a week or less via time steeping, that process eliminates that week’s need. For longer steep juices, I can shave about 80% off the wait time. I’d love a full on 30k plus RPM high shear homogenizer, but the wallet says no…

I have used this method a lot and it does work for me this way. @anon36682625 helped me develop this process with the equipment I have, and it is effective. I used my wife and daughter as guinea pigs, with using steeped vs. mechanical processed juices and they were not able to discern a difference. They did not know what they were participating in so I am confident there was no bias. He’s done so much more testing than I’d ever want to do, and I trust his word. I’ve seen the results myself so I’m good with it.

I would not make these claims unless I was 100% confident in what I am relating. I have made all my juices with high shear devices for well over 2 years. While expensive, the time saving is worth it to me plus I can create a recipe “on the fly” and know exactly how it will turn out without having to wait. I simply add ingredients a little at a time and test with a dripper. While there can be minor changes over the course of a 2 or 3 days with some, the changes are insignificant.

It’s nice to see that several have viewed the Silverson video linked above so they can have a visual image of how high shear devices really work. In every process demonstrated they make the point that aeration is minimized or completely eliminated. High shear is the way most products are made at the commercial/industrial level. A few Silverson customers:

The cloudiness or tiny bubbles produced in the process are not from air being injected, rather they are from cavitation produced by the hydraulic pressure developed by the mixing chamber and rotor/stator. As Walt pointed out, a minute or so in an ultrasonic makes the mix clear as water. Cavitation is how ultrasonic devices (sonicators) process and homogenize. In modern wine making, sonicators turn a year in a barrel into a day or hours. If anyone likes, I can reference peer reviewed university studies.

As far as mag stirrers, they work, I don’t think as well, but they work providing you don’t send your flavors out into room air. Walt’s plugged flasks or saran wrap work very well though I would avoid a strong vortex. VG is much heavier and centrifugal force will send it to the outside of the mixing vessel impeding mixing. A strong vortex will inject air.The video demonstrates the problems with a stirrer or conventional agitator.

mixing/infusing flavor materials suspended in solvent into VG is our task. VG is the the hurdle to overcome;

Quoting the granddaddy of vape flavorings Massimo Mancini- FlavourArts owner:

On the use of PG vs VG for making concentrates:

“Because there is a chemical reason. VG is a poor solvent for flavor material. Flavor materials are mainly (apolas? unknown term to me) which means they are not water logging. So you need a solvent as PG which is safe, which is clean, and that can keep all the flavor material dissolved properly. If you do the same flavor and you use VG instead PG as a solvent, the flavor is going to separate all the time.”

Concerning nicotine we take precautions to avoid allowing air to contact our nic base and store it under refrigeration. Heat will rapidly oxidize nic which in turn will affect flavor. It should be tasteless. The last thing I want is for it affect my flavorings. I leave it out and add at room temp. I am convinced that those who believe heat ruins flavors are mistaken. The problem is nicotine oxidation which occurs at any temp, but is greatly exacerbated by heat.

On the subject of evidence based testing, there can only be one variable.

Its DIY, DO IT YOUR WAY.

Well put my friend. In regard to the gasses formed by cavitation, what is your take on their composition? I have always wondered about that.

Exactly. There is no downside to time-aging other than the oxidation that will occur during that time period on the shelf. Obviously it isn’t a big deal in our worlds except for darker appearance in most cases. But it is also true that mechanical maturation with heat (adding nic after) is fully effective, with the downside being the added cost.

As he said, DIY is called DIY for a reason, and everyone should mix how they desire too. With both methods being effective, there’s no reason to shout down one or the other.

My guess is H2 (hydrogen) or O1 (oxygen) formed by the hydraulic pressure in the work-head causing particle disruption of H2O1 (water) by intense speed and energy. (shear effect) Both VG and PG contain water and it is my understanding that so do the flavor ingredients. Even Ethanol contains distilled water. But that is only a guess.

The vent holes above the stator and the one above are relieving pressure keeping liquid from being sucked up further and spewing out the vents. Some air may be entering from those vents but I really don’t see how that could happen. I’ve had liquid be sucked up to the top bearing which leads me to believe its time for a new PTFE lower bearing.

Don’t buy one if you need it. I can easily make you one since we have the same 10 mm probe.

Makes a lot of sense. Thanks also for the offer. I’m good at the moment but who knows when the need will arise.

vaped snozberry all day today usually i have to wait a 2 weeks for the orange to blend in with the other flavors - but it was very well blended using the homogenizer. im not pro but i would say using the homogenizer cuts down on the steep time. amd im probably spending your money @SmilingOgre. i think its worth it .

Nope, nope, nope… not going to let the shinyitis kick in. Looking nice, I trust that it works well but I don’t need it

I already have more juice around me than I can vape, this thing would make it even worse.

Ya, you did. It will be here Wednesday. The thing that excites me the most beyond price is the 18mm head. That’s twice the size of my probe. I have difficulty getting everything moving in larger flasks. The other thing is the stand. Using the hand held is very cumbersome. Since I last used the hand held, I changed up flavor manufacturers which made a huge difference in my finished juices. Now that I have that more stabilized it’s a good time to try the homoginizer again.

Oh come on… Think how cool it would look next to that snazy high accuracy scale. A mad scientist’s dream!

As usual you are right on the target. The 10mm really isn’t very good for anything much larger than 60ml. I’m a lazy ass and kept them small so I could mix in Boston round bottles. I want a bigger one myself. ![]()

For the price, I’ll make the bet. Down side is we loose about 10~15K rpm but I’m not sure that is necessary for multi viscus juice. I’ll know in a few days I guess. The cost of an 18mm probe would be out of my reach from any of the standard manufacturers.