It is a software glitch not much we can do about it until it is fixed and updated - there is a thread about it

Just made a successful (minor) post edit - and it went through and posted OK ! Good news, it seems ?

I get the feeling that while something around 30 days time of cool-steeping (following your ~8 Hour warming-phase performed) is a minimum, that (even significantly) longer cool-steeping times is not a negative ? Having some stock to vape now, I may try extending the cool-steeping time of ~200 ml of in-process C&D Red Virginia Ribbon (where I’m trying out a 67% PG, 33% VG solvent), out of curiosity. Perhaps more complex flavored and/or pressed tobacco blends might warrant the longest times ?

Not at all. ![]() I see it as just giving the tobacco flavors longer to leach out of the leaf into your solvent. Once you start building up a stock of extract, it’s easier to let the newer macerations just sit for months on end.

I see it as just giving the tobacco flavors longer to leach out of the leaf into your solvent. Once you start building up a stock of extract, it’s easier to let the newer macerations just sit for months on end.

Good to know your experiences/impressions regarding that. It makes sense, in terms of extraction.

Am looking into one potential issue surrounding that (not a simple picture). It looks like there may be specific reasons to reduce final filtering pore-size to no more than 2 Microns (with no leakage). The issue cannot be disposed of by exposure to (even very) low temperatures, or by high temperature exposure at temperatures that are less than ~70 *C (158 *F), either. This is problematic, because:

Time-frames involved are not lengthy (compared to a 30-day process). Problem increases over time, and is ubiquitous environmentally. (Finalized) extract storage at lower temperatures might be indicated. Will research what I can carefully, and try to consult those who know more than I do about the subject.

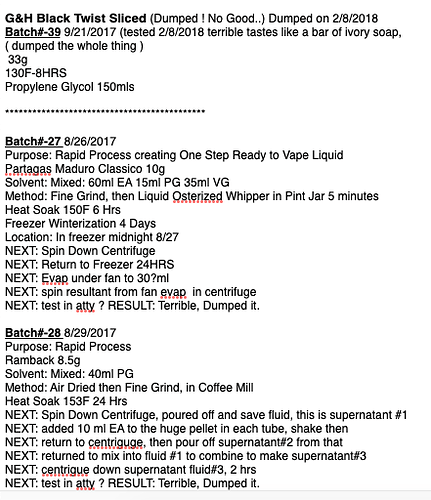

As far as high temps at extended initial heat bumps, I tried a few of those experiments myself. Here I can say that high heat for extended times is a disaster to a NET extraction. I keep extensive lab notes. Here is a cut and paste of some of my notes related to this:

You can see from the above that all kinds of experiments can be performed. You will gain a lot of valuable information from this. Keep accurate notes.

OK Have Fun ! -

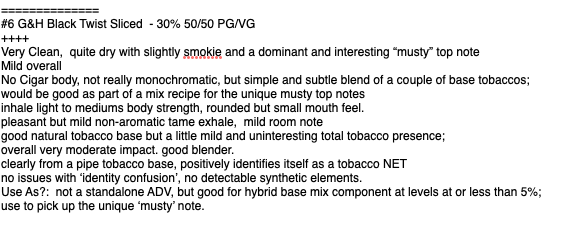

So, @50YearsOfCigars… What do you think went wrong with your extraction on G&H Black Twist Sliced?

For me, this is one of those tobaccos which only cool steeped for 30 days after a heat assist start @ +/-125* F… it resulted in a quite palitable extract. I had a feeling, seeing as how the tobacco was super dark and fragrant prior to maceration, that it wasn’t going to take long for it to come to fruition in the steep jar; just a hunch.

Perhaps it is one of those tobaccos which doesn’t benefit from a super long steep time.  And just might be one which doesn’t need a heat assist start at all… rather, just stick it in a jar to cool steep with a shake every now and then?

And just might be one which doesn’t need a heat assist start at all… rather, just stick it in a jar to cool steep with a shake every now and then?

Well I think it was the 8hrs at 130F that killed it !

The reason I say is that both you and I extracted it “normally” and got a good vabable result. Follows here is my tasting notes from your sample, and these match my notes from my 'regular extraction. So there was something in that blend that reacted with the long heat cycle and caused some component of the mixture to completly take over and dominate the extract in a very bad way.

This points to the fact that all blends will react differently to excessive heat cycle, and we should probably be very careful to make a blanket statement that “all excessive heat cycle processes are always BAD”… there will always be an exception to any rule - some tobacco samples might do quite well with that technique, but it is worth noting that I have not found that “exception”, so in the face of that experiece, I will call it a rule.

If you extract it “normally” you get this 4 out of 5 star rating:

I would say that should stand as a “rule”… and I HATE RULES! ![]()

This issue got me to thinking today, as I’m in the midst of a maceration:

Seattle Pipe Club ~ Potlatch

http://www.tobaccoreviews.com/blend/9706/seattle-pipe-club-potlatch

This blend has a smattering of Cyprian Latakia thrown in to the mix. I’ve found out over time pretty much any Latakia can overpower the other leaf in a big hurry. In giving this blend a whiff in the can, my gut tells me to reduce my heat assist start time by 1/2, lest it yield an extract which is overwhelming in the Latakia department. Thus, this maceration will heat for 4hrs @ 125*F, cool steep for 30 days, and be tested at that time for punchiness. Hopefully, my gut is right. ![]()

P.S. ~ I’m not a fan of the Suttlif Tobacco Co., since I’ve had a few complete NET failures using their tobacco… but, I’m going off the words and reviews of others relating to this blend… perhaps, I won’t be disappointed in the end. ![]() We shall see.

We shall see.

50YOC: I take it that you meant “150 F for 6 hrs” or “153 F for 24 hrs” as your graphic shows here ?

There are 3 different SEPARATE Batchs described, but Yes, I typo’ed one of them but then corrected it. I had 150F on the brain, sorry. correctly noted is however, one at 153F and one at 150F. -But, at the time I did that extract I was using a continuous temp controlled water bath, so the insides of the jar (and therefore the extract sample) was held to 130F continuous for all those 8 hours ! - I no longer use that technique. Now I use an ultra-sonic machine and cycle heating / cooling stages over time. This brings the extract sample in question to a normalized reading not over 110F. -So the point is that I have backed way off from higher temp continuous immersion, and now am quite suspicious of that technique. Like @Kinnikinnick says, it is all experience based.

Yikes, that is a “sobering” (so to speak) observation (understanding that various blends may possibly differ). Nevertheless, there (likely?) remain some common (to most all tobaccos) molecular entities - and it might seem that - given that the much longer time period (in cold-maceration) given for solvent(s) to do it’s/their thing, perhaps erring on the side of caution (temperature-wise) may indeed be prudent ?

I have run 1/2 Oz of PS Luxury Bullseye Flake through the ~8 Hour at 117-137 *F warming phase already (along with my other tobacco stocks). Perhaps I’ll try running the remaining 1/2 Oz of that blend with a cold (room temps) maceration process only, in order to provide a means for taste-comparison.

.

Perhaps neither here/there. Have noticed (when gently stirring) a certain tactile sense of “crispness” (a seeming semi-hardening of sorts) of the leaf-bits that I have warmed, not long after the brew reaches temps in the range of 117-137 *F. That “hardness” seems to decrease over the 8-hour warming times. (Perhaps) leaf-bits initially take-up warm PG (or PG/VG) solvent into their structures, initially expanding from inside, but those structures slowly become more porous, thus relieving such internal pressures.

Give it a shot! ![]() Many folks just cover the tobacco with their solvent and stick it in the steep closet. This could very well be the method that’s right for you? You never know til you try it.

Many folks just cover the tobacco with their solvent and stick it in the steep closet. This could very well be the method that’s right for you? You never know til you try it. ![]()

Yes, I will use the same tobacco-prepping process and 100 ml of PG (only), and possibly give it longer to “macerate” at room temperatures than the ~4 weeks of the initial PS Lux BE run. This will likely lead me towards temptations to grab and shake-up the (already compressed, thus a bit chunky/stringy) leaf-bits more frequently (and consider changing my handle to “Raven Daly & Knightly” …  ). Seems like if it’s useful to ultrasonically vibrate these “brews” then my little old arms can’t do much if any damage ?

). Seems like if it’s useful to ultrasonically vibrate these “brews” then my little old arms can’t do much if any damage ?

This brings up an interesting question about some of these “tinned” tobaccos. I recently ordered this exact tobacco, the Solani, and I will clip here some comments from a PM that went back and forth from my mentor @Kinnikinnick about this subject.

I post this here to help tp perk up the ears of all NETers out there, that sometimes things are not what they seem at first ![]()

Filtering my Solani Aged Burley over the next couple of days

I just received my tin from Cup O Joes but this labeling doesn’t sound like what I thought I read on the reviews ? I don’t remember anyone mentioning these licorice and chocolate toppings ? - Did I get the right stuff ?

The review at tobacco reviews states " A very natural blend with absolutely no additives or flavors - a true burley blend."

I guess I am a little confused. ???

Kinnikinnick

Hummm… guess I should have read a little further down the page where this appears:

At first: This flake ISN’T unflavoured NOR UNSUGARED! - K&K states on their website “Chocolate Flavouring”, and only mentions White Burley as ingridient.

And the official additive list reveals it has ~5mg of flavouring and ~168mg of added sugar on 1000mg of tobacco: https://service.bmel.de/tabakerzeugnisse/index2.php?detail_id=104712&site_key=153&stichw_suche=solani&zeilenzahl_zaehler=14 I just hate this kind of false advertisment (usually known from K&K…) “oh, a oh so natural blend, no sugar added.” . . . 168mg of sugar added… as well as PG!

It would be nice if the vendors of tobaccos had their facts straight and didn’t just copy and paste descriptions which are incorrect or out and out lies.

About the only way one will get away from additives in tobacco is to use whole leaf varietals from vendors such as:

https://www.leafonly.com/index.php

On the other hand, it’s a safe bet to say that tobaccos, minus the ones you might grow yourself, have some kind of man made product on the leaf (ie: pesticides). So, when/where do we draw the line with regards to the tobacco we use for making NET?

Me? I’ll admit… I do turn a blind eye to what might be on the leaf from vendors/manufacturers… tinned or whole leaf. In the end… I’m not a purist. However, it would be nice if the vendors/manufacturers would be up front about exactly what is on the leaf. But, WHO AM I KIDDING!  We’re talking about folks who sell a known carcinogenic plant product to humans.

We’re talking about folks who sell a known carcinogenic plant product to humans.

Oh well… Me =

(as I inhale some very tasty vaporized Dunhill Royal Yacht!)

(as I inhale some very tasty vaporized Dunhill Royal Yacht!)

Here are some excerpts from a 2013 report (found in Section II - Pesticides in Tobacco, on doc Page 3):

Tobacco is produced by a large and powerful agricultural industry that makes significant use of pesticides to protect the growing crop and harvested tobacco during curing, manufacturing, and storage. As many as 16 separate applications of pesticides are recommended by tobacco companies just in the interval between greenhouse seed sowing and transplantation into the field … By the early 1990s, there were at least 37 pesticides approved by the EPA for use on tobacco crops in this country, although since that time many of these materials have had their registrations for use in tobacco cancelled … While EPA approvals address requirements for worker protective gear and health monitoring, application rates and frequencies, pre-harvest intervals, and other factors, the EPA has determined that pesticide residues in finished tobacco pose a negligible incremental risk to health when compared to the direct effects of nicotine and other combustion products in tobacco smoke. The EPA has chosen to not regulate pesticide residues in domestically grown tobacco, and it does not issue residue level guidelines for tobacco products at this time. … in 2011 when this law would seem to have been enforceable, the FDA issued a statement to the tobacco industry that included the following statement: “To determine whether there are pesticide residue tolerance levels applicable to domestic tobacco, the Food and Drug Administration (FDA) consulted with the U.S. Department of Agriculture (USDA) and U.S. Environmental Protection Agency (EPA). According to USDA and EPA, under their laws there are currently no established tolerance limits for pesticide chemical residues that apply to domestically grown tobacco." … in this country pesticide monitoring has been largely left to the discretion of the industry, with few exceptions, described below. The U.S. tobacco industry is known to have vigorously lobbied against stricter pesticide controls and public disclosure of residue levels (McDaniel et al. 2005). The situation in the European Union is similar. … The EPA regulates which pesticides can be applied during production and subsequent manufacturing, but in general it has not regulated pesticide residue levels in the final products of domestic producers.

After ~7 weeks of room temperature maceration (only) of 1 Oz of C&D Red Virginia Ribbon in 200 mL of PG (split into two small mason jars), the aroma of the extract is distinctly “hay-like” (and not particularly inspiring) - as opposed to Kinnikinnick’s (and my own initial previously performed) ~8 Hours warming (at ~125 *F) followed by ~4 weeks, both of which have a distinctly pleasant and rather interesting “fruity” aroma. Will be (more objectively than so far) comparing taste-results in a small RDA allowing flavor comparisons. In this (C&D RVR) case, it seems that the ~125 *F initial warming phase is (probably) a desirable procedure - with or without any possible decompositions/reactions. Perhaps a somewhat lower warming temperature for a somewhat longer warming time might be in order (in an attempt to address above temperature concerns) ?

I’m of the opinion, the warming procedure aids in releasing certain quality characteristics of the leaf, which are otherwise left undiscovered using a room temperature maceration process. But, to each their own… ![]()

Hmmm. I’m pondering the juxtaposition of the following related comments posted by 50YearsofCigars:

“Reactions” that would evolve the heat that I had described - but not a statement of “no chemical reactions”.

The situation (surrounding advisable maximum heating-phase temperatures) being complex, and potentially different for various tobaccos, perhaps 110 *F (maximum sustained) is an advisable (conservative) limit ? It would be nice (if it may be possible, via either theoretical and/or empirical means) to arrive at a particular (deemed “safer”) temperature multiplied by time duration product to work with and apply (for each tobacco blend, etc). Perhaps leaf-bits “scald” (in their own sort of way) as temperature approaches 120 *F … ![]()

As mentioned, leaf-bits (in PG) seem to become a bit “crispy in texture” for the first few hours (at ~125 *F).