Below is a link to a forum (about NETs) that “50YearsOfCigars” started publishing last Summer:

http://diy-tobacco-net.epizy.com/index.php?i=3

Some of his thoughts about NETs (and other endearing sentiments) are expressed in this post.

.

I’m a NETs only fellow. It’s not that hard to do (once one knows what they like and want, that is). It just takes the patience to wait a while, and the willingness to filter extracts to a few Microns. That accomplished, just “shake and vape”. Avoid processed cigarette Tobaccos. I like Virginia / Perique / Cavendish pipe blends. This helps to support the high quality Pipe (and perhaps the Cigar, and less processed) Tobacco industries. (IMO), PG is the best solvent. VG is too thick, Ethanol has to be removed, and Water grows “critters”.  The aroma of my Va/Per/Cav DIY vaped juice is very similar to (unsmoked) Lucky Strike cigarette Tobacco.

The aroma of my Va/Per/Cav DIY vaped juice is very similar to (unsmoked) Lucky Strike cigarette Tobacco.

Having a stock of Nicotine and Glycols, NETs are the “perfect foil” against the War on Synthetic Flavors !

My (rough) process (with very kind assistance and support from our honorable friend @Kinnikinnick):

Add ~6-8 mL of PG per Gram of source Tobacco (make sure leaf bits are submerged in the PG solvent). Heat to ~110-120 *F for 6-8 Hours time (gently stirring a bit). Seal and store at room temperature in a dark place for ~6-8 Weeks time. Strain and filter (ideally, eventually to ~2 Microns). I use 1.5 Micron acceptance-size filter-paper (which will eliminate untoward critters and their spores). Store in sealed glass in refrigerator.

Notes: Little Nicotine exists in NET extracts. Add Nicotine, PG, and VG to preference (up to ~20% NETs). Best with single-coil RDA/RTA. Better (and safer as well) using lower vaping Temps, in combination with higher added Nicotine concentrations. I build single SS 316L coils and use Rayon (“Cellucotton”) wicking. Freebase Nicotine works fine. Wicks will require fairly frequent replacement (relative to synthetic flavorings).

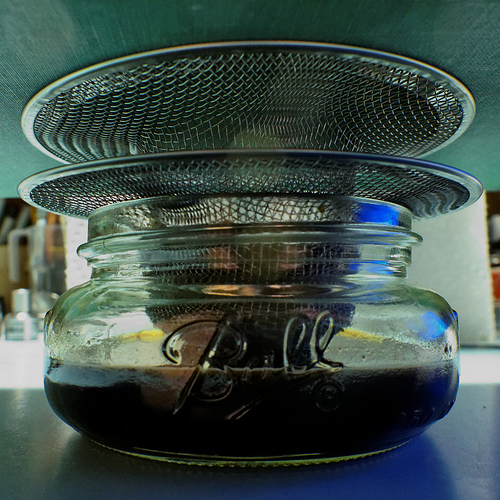

Here’s a series of images that show my various extraction contraptions (both on break, and at work):

.

.

.

.

.

.

.

The “Marlboro secret” - involving the addition of Ammonia in processing the Tobacco:

“The SECRET and SOUL of Marlboro - Phillip Morris and the Origins, Spread, and Denial of Nicotine Freebasing”

Philip Morris and other tobacco companies have been using ammonia in their manufacturing for more than half a century, and for a variety of purposes: to highlight certain flavors, to expand or “puff up” the volume of tobacco, to prepare reconstituted tobacco sheet (“recon”), to denicotinize (reduce the amount of nicotine in) tobacco, and to remove carcinogens. …

… Marlboro’s commercial success catalyzed efforts by the rest of the tobacco industry to discover its “secret,” eventually identified as ammonia technology, and how Philip Morris later exploited the myriad uses of ammonia (e.g., for flavoring and expanding tobacco volume) to defend itself against charges of manipulating the nicotine deliveries of its cigarettes.