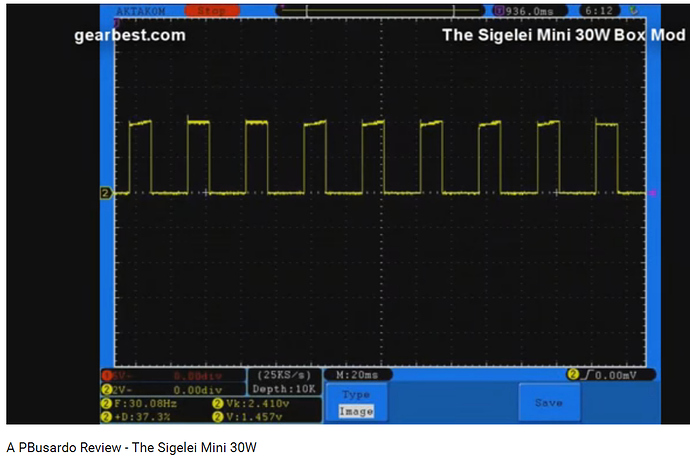

My mainstay mod is the “illustrious” Sigelei 30 Watt Mini (acquired dirt cheap; built like a tank). Have over time formulated a (for me preferred) Virginia/Perique/Cavendish NET flavoring recipe developed with Sigeleis (in Power control mode, which uses 30 Hz PWM). Have worked down to ~6 Watts (~3 Volts into ~1.5 Ohm single SS 316L coil in the case of the Magma RDA used in the tests described below; and ~2.5 Volts into a ~1.0 Ohm SS 316L coil in the case of Tobeco Kayfun 5 RTA that is my normal reference vaping rig). My e-juice used is ~1.5% (15 mg/ml) Nicotine base in ~60/40 PG/VG with ~20% NET extract flavoring.

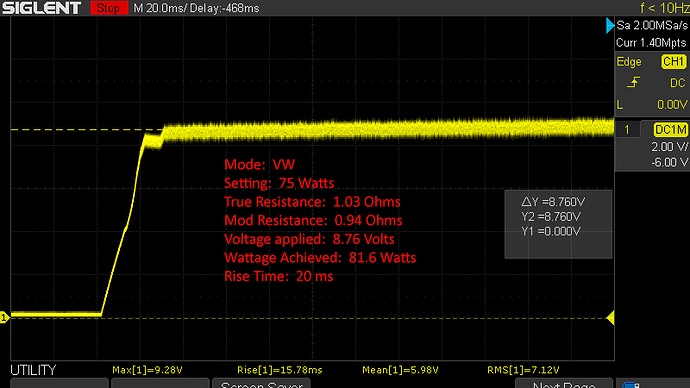

Recently I acquired an eLeaf Pico 25 mod (mostly in order to have a Temperature Control - or, at least, a Temperature Limiting device to try out). In TC as well as in Power mode (as seen in PBusardo’s YouTube review of the similar Pico (75W) predecessor - albeit with an earlier chip-set inside - and including some nice oscilloscope views shown soon after the time where the video-link starts-out), there does not appear to be much of any observable AC ripple to speak of on the (nearly DC) drive-voltage (in Power or TC mode).

This (nearly zero AC ripple) drive-voltage all sounded well and good - until my tasting “palate” has firmly and repeatedly “told” me that - at least in the case of my NET flavorings developed using the Sigelei, and when using the Pico 25 in Power mode in order to keep things simple - the same NET-flavored juice in the same RTA tastes rather bland indeed when using the Pico 25. I do not think that the differences in heat sinking of the RTA base by the Sigelei and Pico mods are responsible for these repeatedly noted differences in taste.

Have measured the RMS AC voltage across the 1.5 Ohm coil with 3.0 Volts drive (6.0 Watts). The RMS ripple is a whopping ~1.9 VAC (with the fundamental frequency at the 30 Hz PWM repetition-rate). I have very nearly convinced myself that it is that AC Power Ripple that I like ! I do think that something “magical” happens (due to the AC ripple) that “clean” DC drive-levels simply do not seem to provide regarding taste.

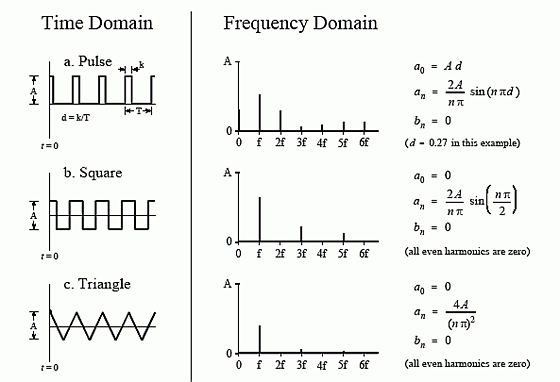

Yes, the thermal time-constant of the coil-wick interface acts as a low-pass filter (thus, to some extent expected to attenuate the resultant “ripple” in the coil-wick interface temperature). However, it’s only 30 Hz, and ~1.9 VAC ripple on ~3.0 VDC is quite a lot of variation in the value of the (instantaneous) power that is dissipated in the electrical load of the coil assembly. Something is different - and I think that this may be it.

(Perhaps) temperature oscillations around the ~160 *C range at which several types of sugars decompose where the “interesting moments” occur on the temperature up-swings - but seem to fade once temperatures above that ~160 *C range exist. Such sugar(s) decomposition effects (may) not be unique to NET extracts.

Posting this in order to inquire as to whether others (may possibly) have formulated any similar impressions (regarding older, lower frequency Power PWM mode mods) ? Or perhaps, few mods in popular use these days use anything as “funky” as 30 Hz PWM ? Any observations by others that may be similar interest me.